Innovative manufacturing for prototype projects and production

3D printing builds parts layer-by-layer straight from your CAD file, so you skip moulds, cutters and long waits. Designs can change overnight and be in your hands within days, cutting risk and speeding up product launches. From a single show-and-tell model to a small batch of end-use parts, the same digital workflow keeps costs low and quality repeatable.

Choosing the right process comes down to four essentials: accuracy, strength, material behaviour and surface finish. That’s why IPFL offers every major 3D printing technology under one roof:

PµSL delivers micro-features down to 10 µm for medical, MEMS and microfluidic parts.

SLA produces smooth, high-detail models ready for painting or clear finishing.

SLS and MJF fuse nylon powder into tough, production-grade components with complex internal geometries.

PolyJet prints multiple colours and shore-A rubbers in a single build for realistic prototypes.

FDM processes high-temperature thermoplastics like Ultem and PC for functional, load-bearing parts.

Whatever the brief—prototype, jig, fixture or short-run production—we match the technology to your needs and ship UK-wide with expert support at every step.

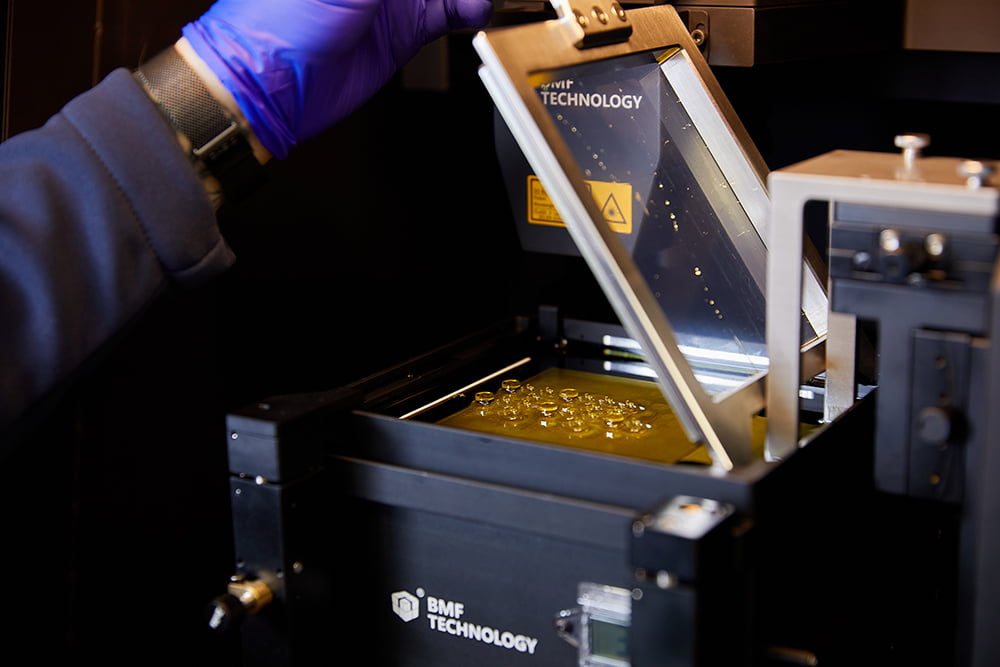

PµSL is IPFL’s ultra-high-resolution micro 3D printing service, powered by Boston Micro Fabrication (BMF) platforms. Using projected UV light to cure resin layers just 2–10 µm thick, it creates complex features smaller than a human hair with ±10 µm accuracy across the whole build. Ideal for microneedle arrays, microfluidic chips, MEMS parts, micro-gears and biomedical devices, PµSL delivers crisp edges, smooth surfaces and true-to-CAD accuracy without tooling. Choose from optically clear, biocompatible and high-temperature resins and receive fully finished micro parts in days—right here in the UK.

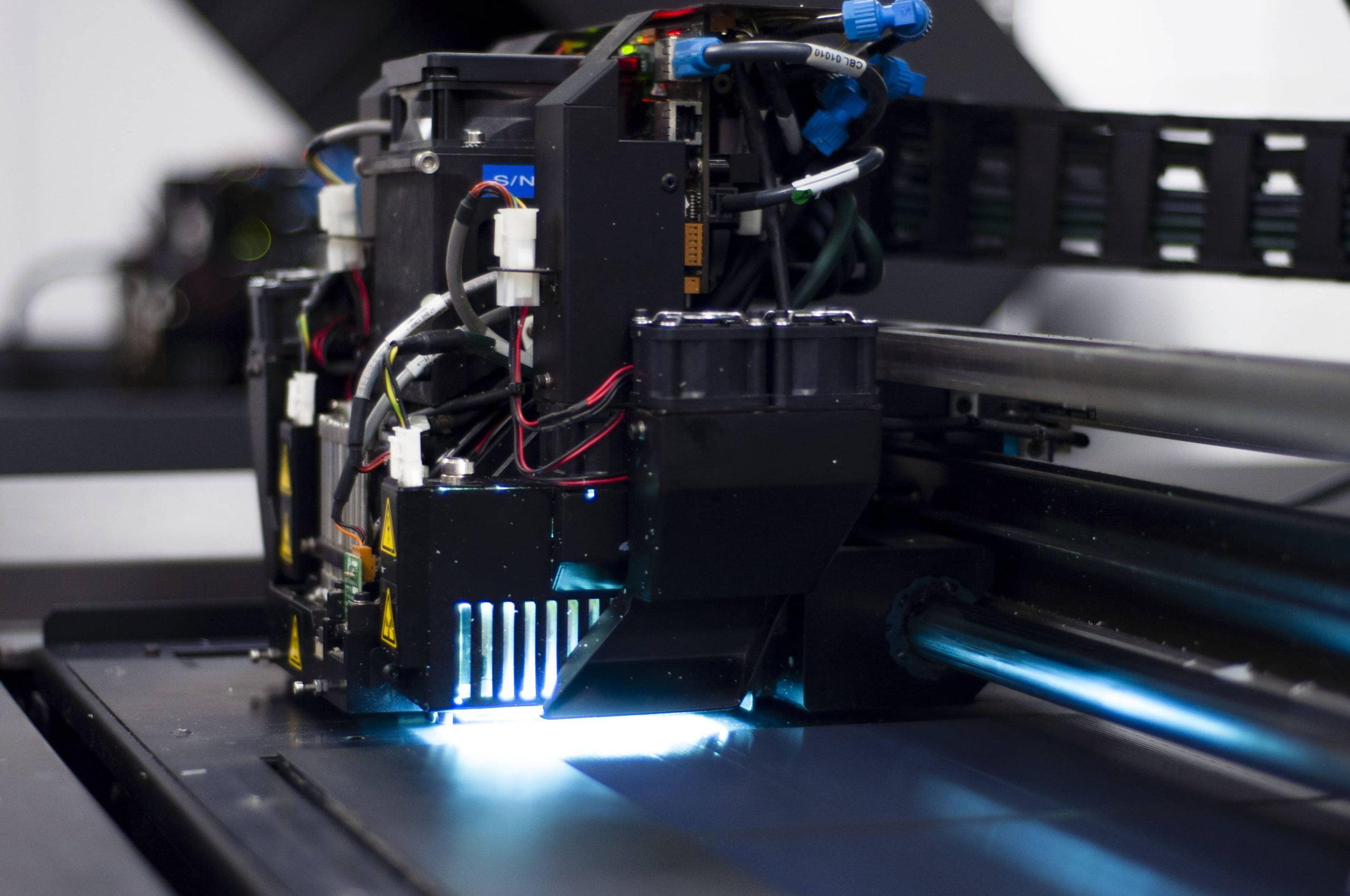

SLS 3D printing fuses nylon and filled engineering powders with a precision CO₂ laser, building tough, lightweight parts without support structures. The result is production-grade components that handle heat, chemicals and repeated stress—perfect for snap-fits, housings, ducting and living hinges. IPFL’s SLS service delivers isotropic strength, intricate internal channels and matte, ready-to-use surfaces in PA12, glass- or carbon-filled nylons and ESD-safe blends. With no tooling costs and rapid UK turnaround, Selective Laser Sintering is the go-to choice for functional prototypes and low-volume production runs that demand durability and design freedom.

SLA cures liquid photopolymer with a precision laser to achieve razor-sharp edges, layer heights down to 25 µm and glass-smooth surfaces ideal for cosmetic prototypes, dental models and transparent components. IPFL offers a full resin portfolio—tough, clear, castable and temperature-resistant—so you can move from concept visuals to functional testing fast while keeping every fine detail intact.

PolyJet jets and instantly UV-cures microscopic droplets of resin, blending multiple colours and shore-A elastomers in a single build. Create overmoulded grips, soft-touch buttons, living hinges and realistic CMF (colour-material-finish) models without assembly. With layer heights down to 14 µm, PolyJet from IPFL accelerates design validation by showing exactly how the end product will look and feel.

MJF deposits fusing agents across nylon powder and fuses it with infrared energy, delivering isotropic strength, fine 80 µm layers and outstanding surface quality. The result: lightweight, watertight parts ready for mechanical loading, snap-fits and enclosures. IPFL’s MJF service ships functional PA12 parts—and colour or ESD-safe options—within days, perfect for bridge production and supply-chain resilience.

FDM extrudes molten filament to build robust parts in engineering-grade materials such as ABS-ESD, PC, Carbon-Fibre-Nylon and Ultem™ 9085. Ideal for jigs, fixtures, tooling inserts and flight-ready components, FDM combines low cost per part with excellent chemical, heat and impact resistance. IPFL’s large-format printers handle sizeable builds while maintaining tight tolerances.

From biocompatible and transparent resins to carbon-filled nylons and high-temperature PEI, IPFL stocks an industry-leading material library. Post-processing services—including vapour smoothing, dyeing, bead blasting, CNC finishing and painting—ensure every part meets your exact mechanical, aesthetic and regulatory requirements.

Since 1969, IPFL has paired cutting-edge additive technologies with in-house machining and fabrication, giving product designers a single, trusted source for prototypes, jigs and production parts. ISO-certified quality, rapid turnaround, and application-driven advice reduce risk and accelerate time-to-market. Upload your CAD file for a same-day quote and design feedback. Our UK-based specialists review geometry, suggest optimal materials and printing processes, and keep you informed from print to dispatch, ensuring a smooth path from digital model to finished part.