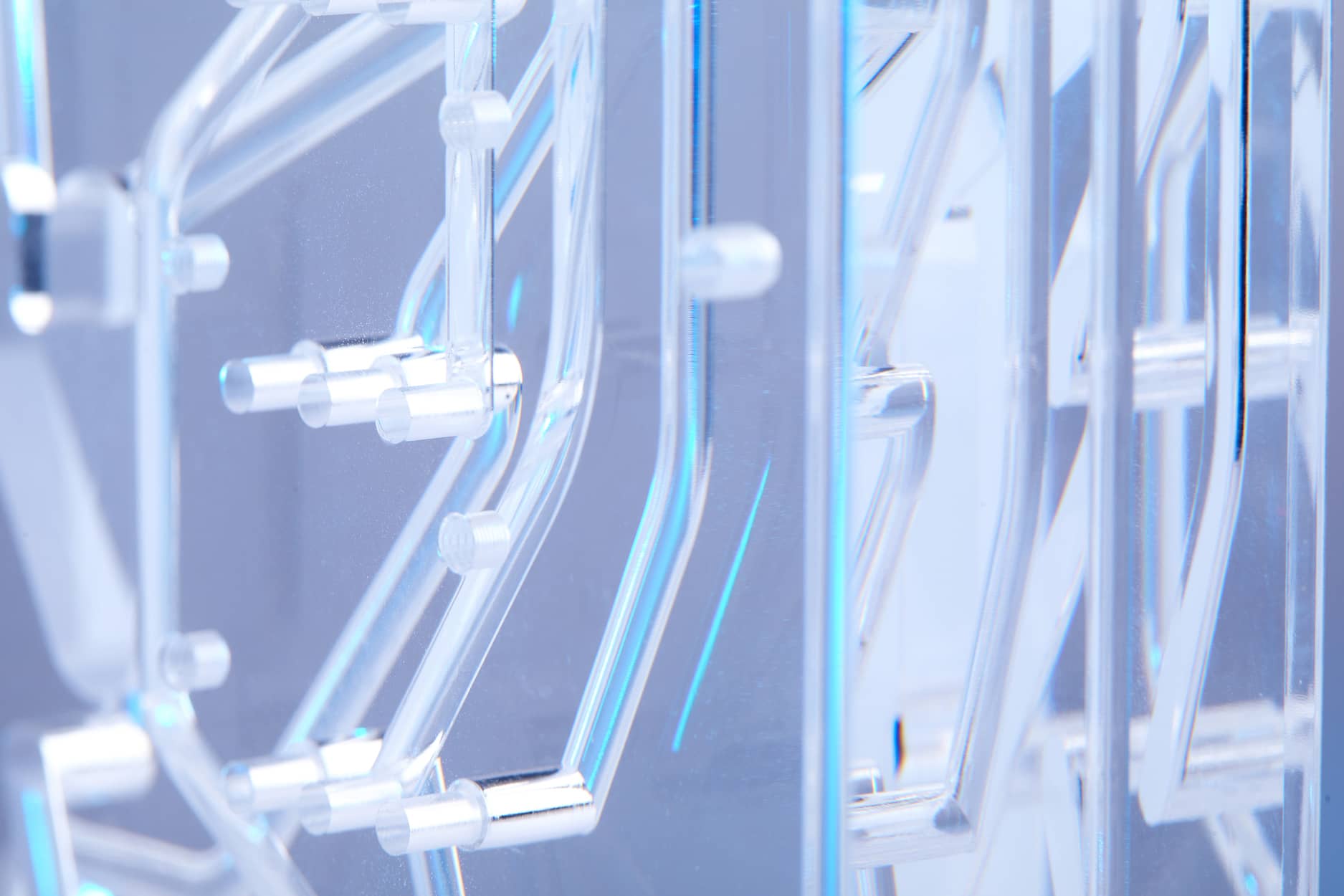

Exceptional precision and finish plastic components

At IPFL, we harness the exceptional precision of diamond machining to create superior quality plastic components. Utilizing diamond-tipped machine cutters, we achieve a level of finish that is unparalleled. This advanced technique is ideal for producing components with ultra-smooth surfaces and intricate details. Our diamond machining service is complemented by a range of other capabilities including CNC routing, milling, laser cutting, and UV digital printing, providing comprehensive solutions for all your high-precision component needs.

IPFL’s diamond machining services are expertly tailored to meet the specific needs of projects that demand exceptional surface finishes and intricate detailing. We cater to a broad range of applications, ensuring that each component, whether a part of a complex assembly or a standalone piece, is machined to perfection.

Our diamond machining is ideal for: