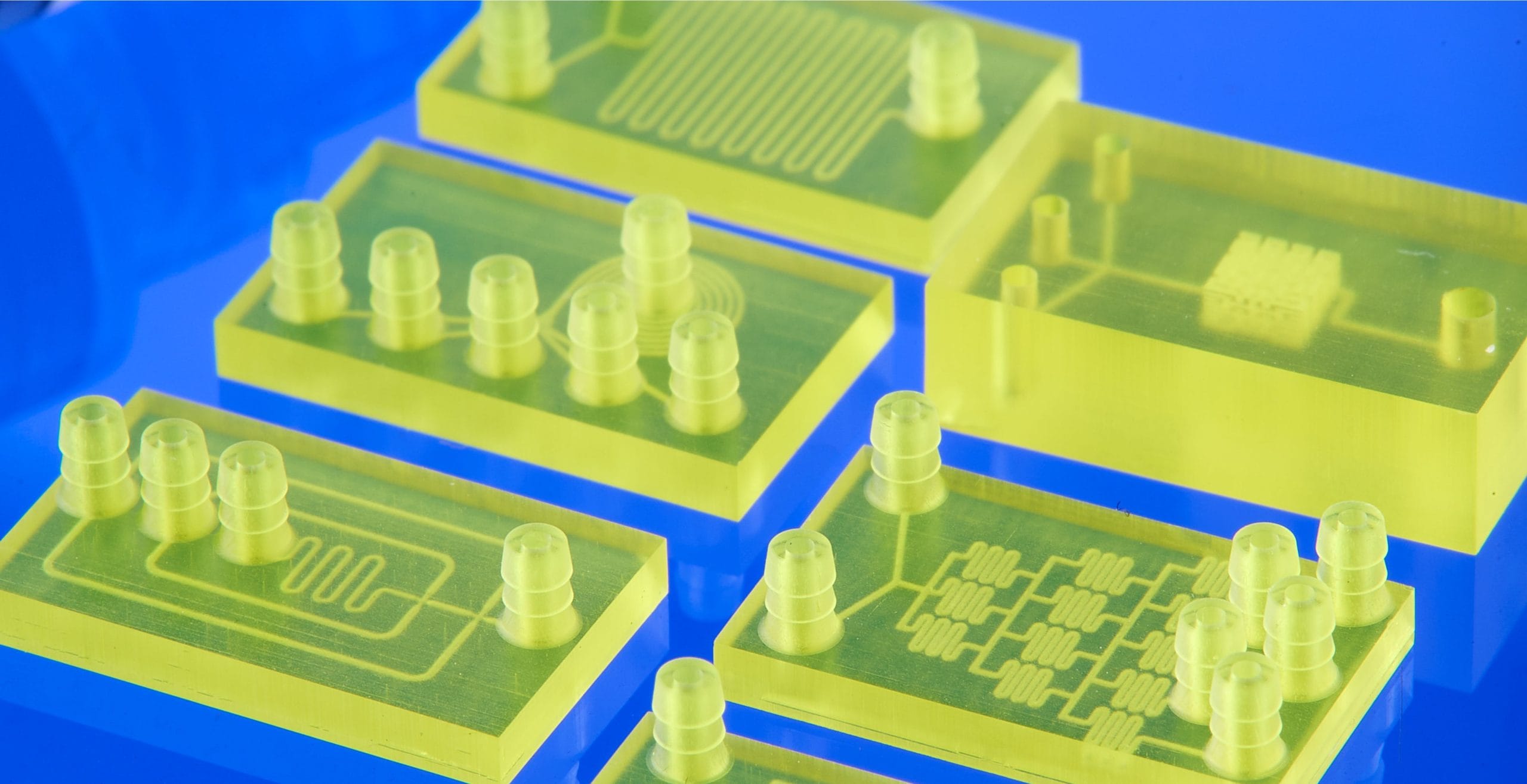

Micro parts. Maximum accuracy. Proven in microfluidics, med-tech, and electronics.

IPFL offers specialist micro 3D printing services for industries that demand extreme precision at micron scale. Using advanced Projection Micro Stereolithography (PµSL) technology, we achieve feature resolutions down to 2 µm with true-to-CAD accuracy. Our micro 3D printing capabilities enable the production of complex parts, fine channels, and intricate geometries for applications in microfluidics, medical devices, electronics, optics, MEMS, and research. From prototypes to small-batch production, IPFL delivers high-resolution micro components that traditional methods cannot achieve.

Micro 3D Printing is the specialised production of highly detailed, miniature components with features measured in microns. Using cutting-edge technologies — including Projection Micro Stereolithography (PµSL) — IPFL can produce parts with resolutions down to 2µm. This allows for complex, micro-scale designs that traditional manufacturing cannot achieve.

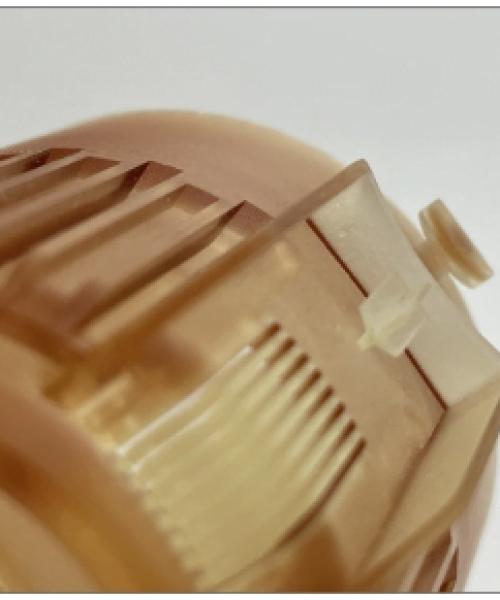

Additive manufacturing processes build precision parts layer by layer. Using advanced photopolymer resins and ultra-fine exposure techniques, we achieve exceptional surface finish, tight tolerances, and reliable repeatability. All essential for critical industries like med-tech, electronics, and research.

| Key Metric | Typical Capability |

|---|---|

| XY resolution | 2–10 µm |

| Layer thickness | 5-40 µm |

| Dimensional accuracy | Down to 3 microns |

| Surface roughness (Ra) | 0.4 µm Top faces, 1.5 µm on side walls |

At IPFL, we combine decades of precision manufacturing expertise with the latest micro 3D printing technologies to meet the most demanding specifications. Intricate prototypes or production-ready micro components, our proven processes ensure exceptional dimensional control, material performance, and surface quality. We support every project with expert consultation, helping you navigate design complexities and material choices to achieve the best possible outcome. Quickly and cost-effectively.

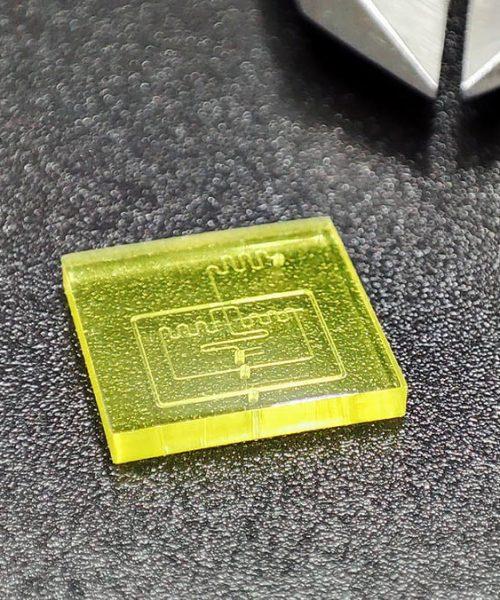

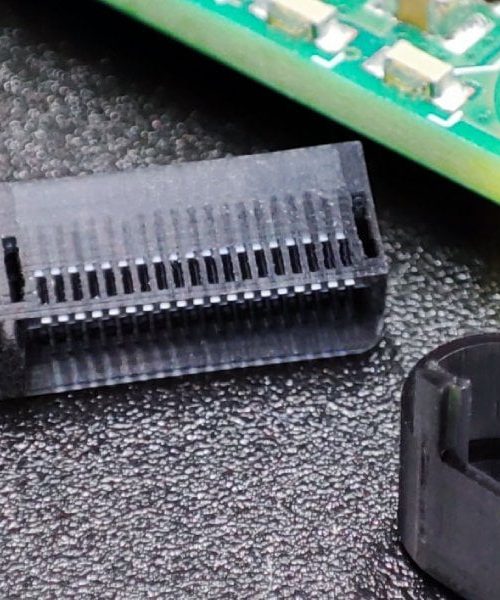

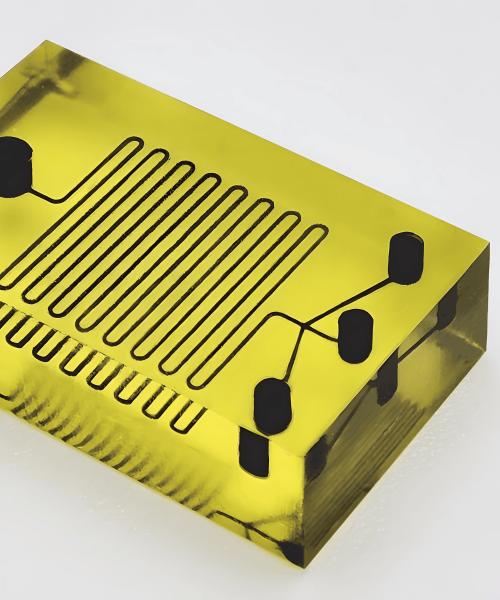

Micro 3D printing unlocks possibilities across industries that demand extreme miniaturisation and precision. From advanced microfluidics for life sciences to miniature electronic components and optical devices, our service enables rapid development of parts that would be too costly or impossible to produce with conventional methods. This technology empowers innovators in med-tech, research, semiconductors, and sensors to accelerate product development, validate designs, and deliver solutions at the cutting edge of their fields.

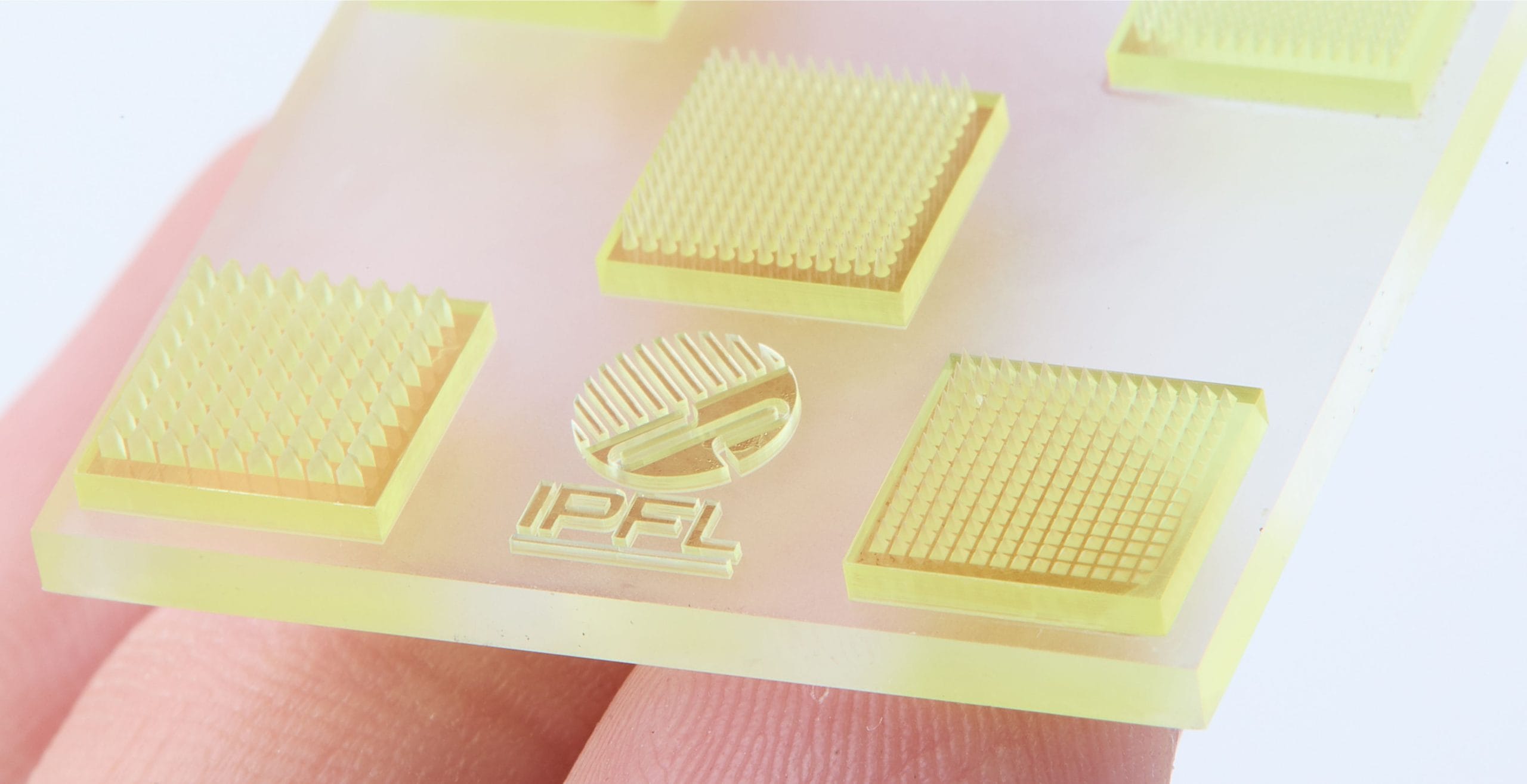

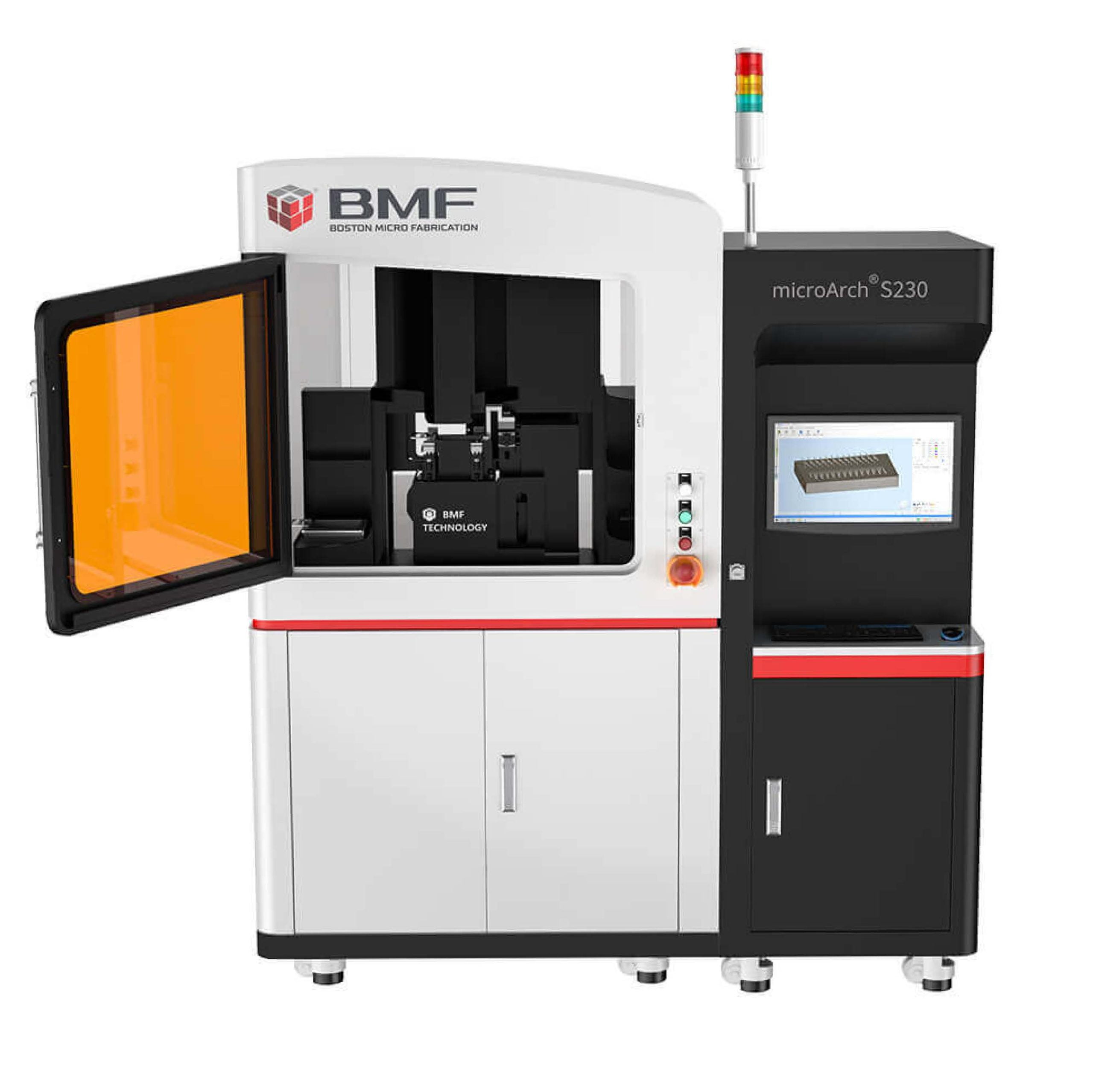

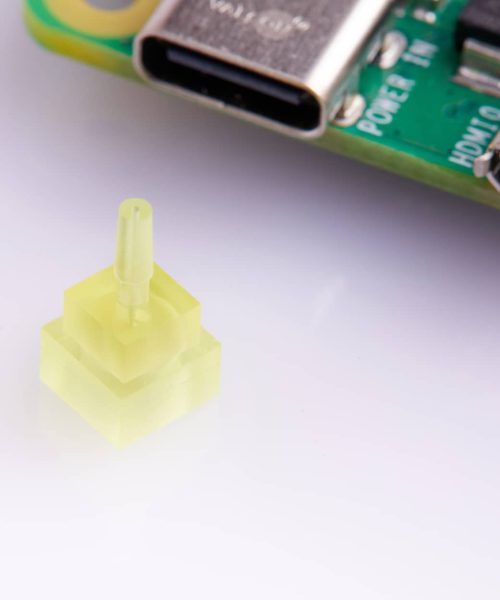

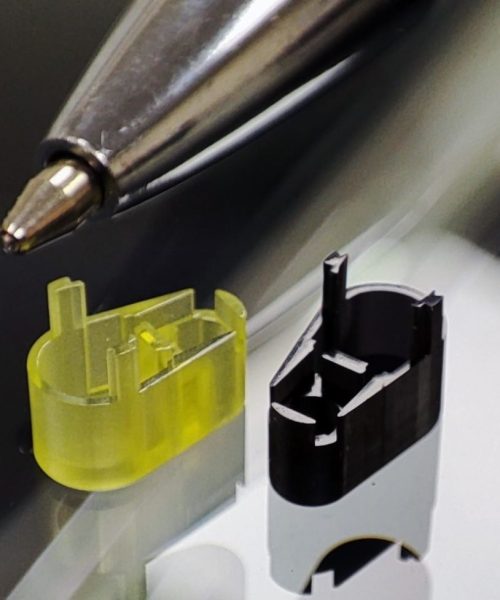

At IPFL, our Micro 3D Printing services enable the creation of incredibly precise and detailed components with features down to just a few microns. Using specialist technologies, including our BMF microArch® 10 µm and 2 µm resolution printers, we transform your CAD designs into physical parts that are product ready. Application in microfluidics, MEMS, sensors, organ-on-chip devices, microneedle arrays, and miniature surgical components.

Our process delivers dimensional accuracy within ±10 µm and achieves surface roughness as low as 0.4 µm Ra. Reducing or eliminating the need for polishing or secondary finishing.

We offer a wide selection of high-performance materials, from biocompatible resins and engineering polymers to ceramic-loaded options, ensuring material properties align with your application requirements. For more complex needs, such as leak-proof microfluidic channels or multi-layer assemblies, we complement our printing services with CNC machining, laser cutting, and diffusion bonding — all performed in-house to create fully functional and production-ready components.

Rapid prototyping, low-volume production, or micro-scale parts with intricate features, IPFL delivers the precision, surface quality, and turnaround speed necessary to keep your projects moving forward. Contact us today for a tailored quote on your micro manufacturing needs.

Our Micro 3D Printing services enable the production of highly precise, small-scale components with micron-level resolution, exceptional dimensional control, and the ability to replicate intricate features directly from CAD designs. Leveraging advanced technologies capable of resolutions down to 2 µm, we produce parts that are simply unachievable through traditional manufacturing or standard 3D printing methods.

Micro 3D Printing at IPFL provides the precision, consistency, and design freedom essential for industries where miniaturisation and accuracy are mission critical.

Using IPFL’s PµSL, features as small as 6 microns can be produce on 2µm resolution equipment. This enables highly detailed geometries and microstructures that standard manufacturing techniques cannot replicate.

Micro 3D Printing can include engineering-grade resins, as well as bio-compatible materials, high-strength polymers, ceramic-loaded resins, and ESD formulations. This allows material properties to match your specific application requirements.

BMF PµSL micro 3D printing process delivers dimensional accuracy down to 3 microns, ensuring tight adherence to CAD specifications.

Absolutely. While micro 3D printing is ideal for rapid prototyping, the precision, material performance, and surface quality also make it suitable for functional end-use components, especially in medical devices, microfluidics, electronics, and MEMS.

Lead times can vary based on complexity and quantity, but prototypes are typically produced within 5–10 working days. For larger volumes or specialised post-processing, we’ll provide a project-specific timeline.

Yes, we can integrate CNC machining, laser cutting, and diffusion bonding with micro 3D printing to deliver complex assemblies, multi-layer microfluidics, and components with enhanced functionality.

Using technologies like IPFL’s PµSL from BMF, you can reliably print horizontal channels 50 µm and vertical holes 10 µm, with aspect ratios up to 500:1 to ensure cleanability