Projection Micro 3D Printing – Precision 3D Printing and Rapid Prototyping

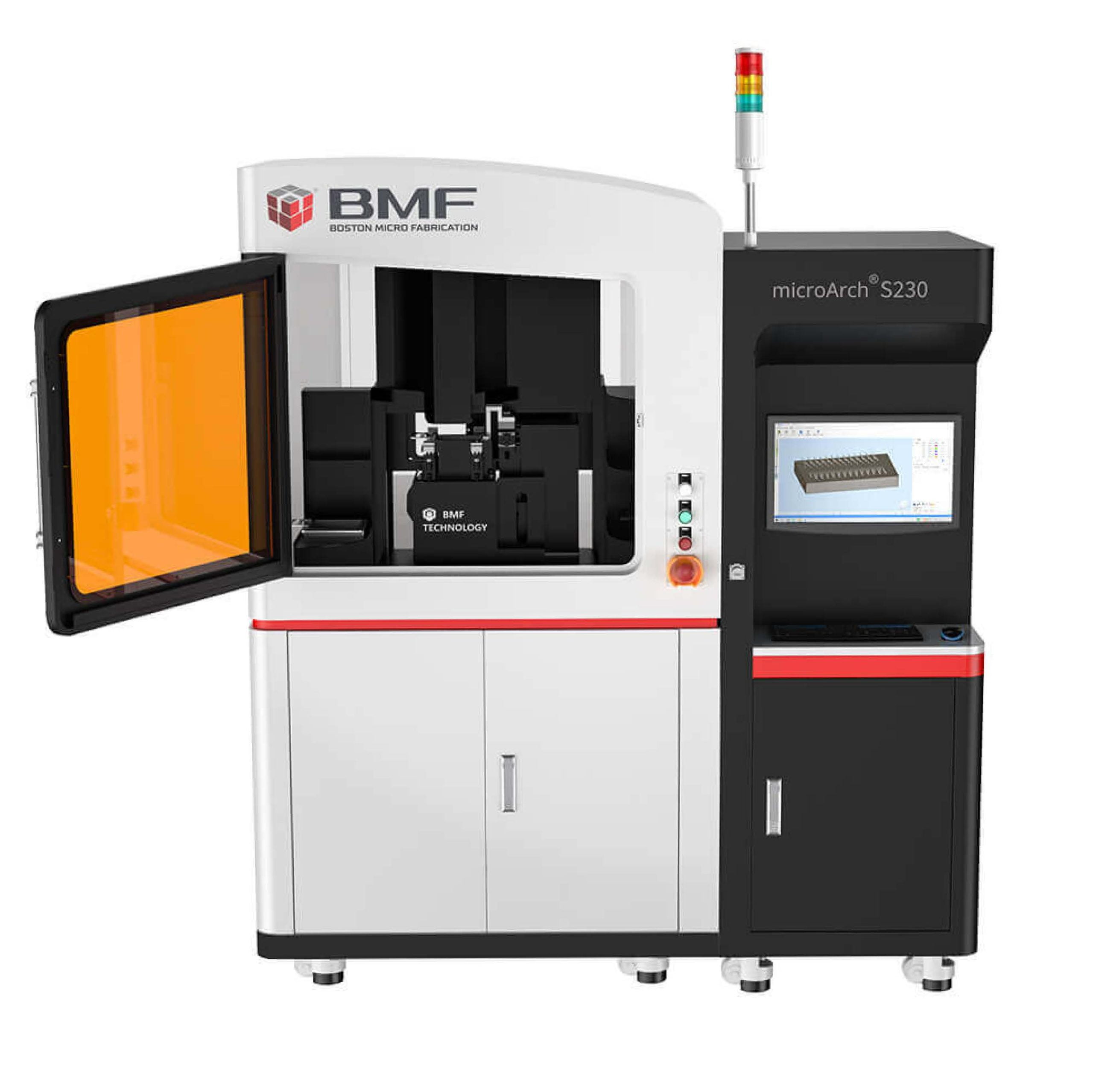

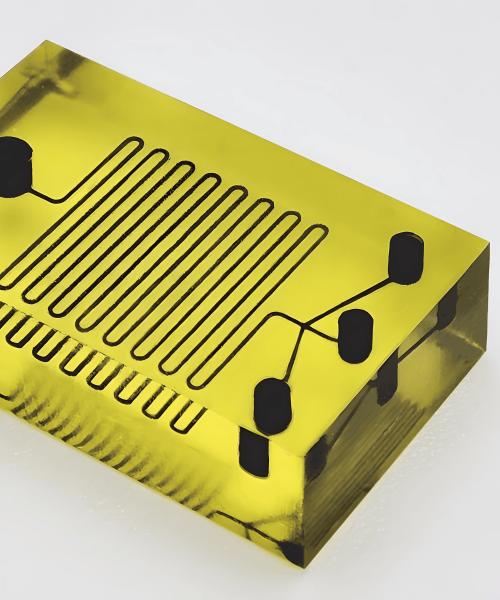

BMF PµSL (Projection Micro Stereolithography) is an ultra-high-resolution 3D printing process developed by Boston Micro Fabrication (BMF). The technology uses a digital light projector (DLP) with a digital micromirror device (DMD) to flash 405 nm UV images onto a vat of photopolymer resin, solidifying each 10 µm-thin layer in milliseconds. By stacking thousands of these layers, PµSL builds complex micro-parts with:

| Key Metric | Typical Capability |

|---|---|

| XY pixel resolution | 2–10 µm |

| Layer thickness | 10 µm standard (optional 5 µm) |

| Dimensional accuracy | ±10 µm or ±0.3 % |

| Surface roughness (Ra) | 0.4 µm on horizontal faces, 1.5 µm on vertical walls |

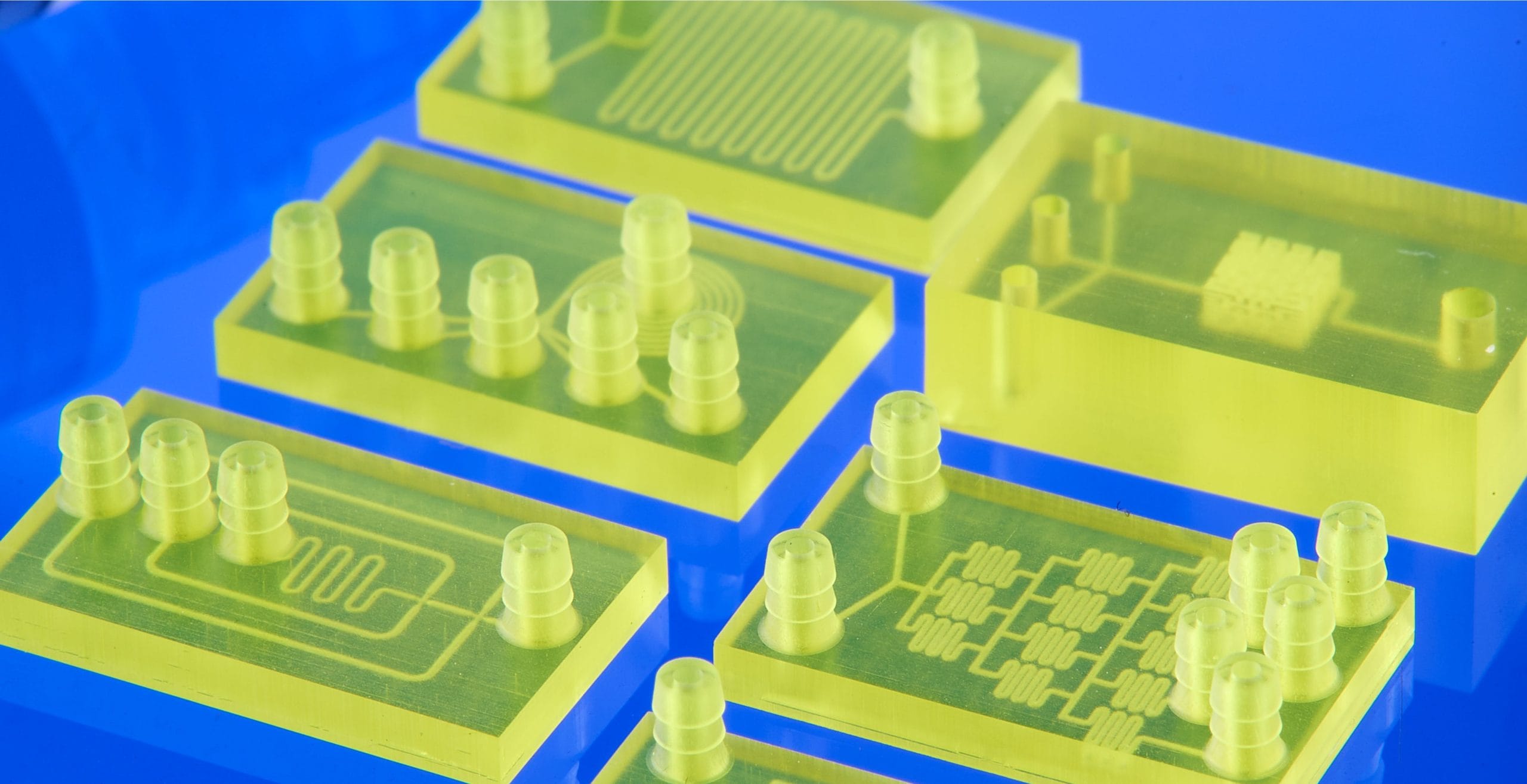

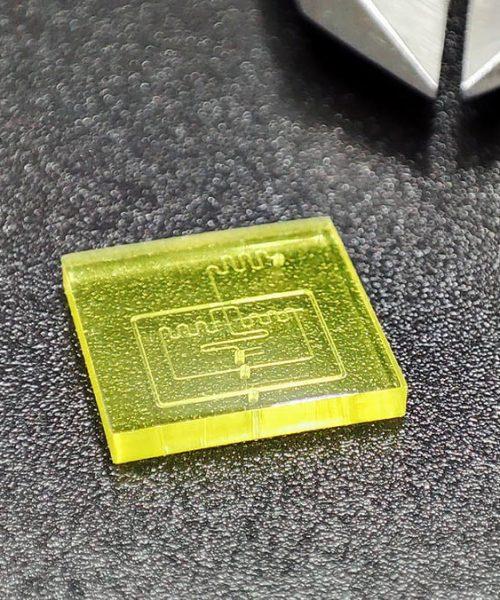

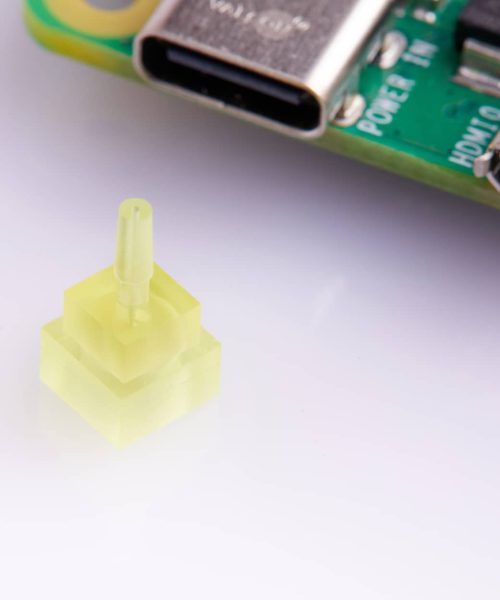

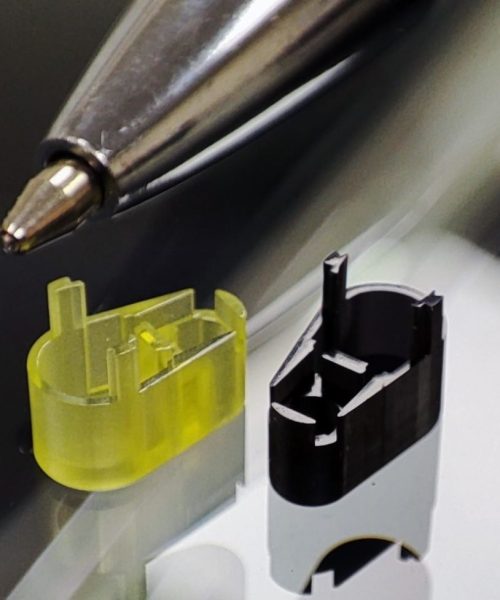

IPFL offers high-precision micro 3D printing services using the BMF microArch® 10 µm and 2 µm printers. These machines turn CAD files into parts with features finer than a human hair, perfect for microfluidics, MEMS, sensors, microneedle arrays and bespoke surgical stents. Parts come off the printer with ±10 µm accuracy and near-optical 0.4 µm Ra surfaces, cutting post-processing time.

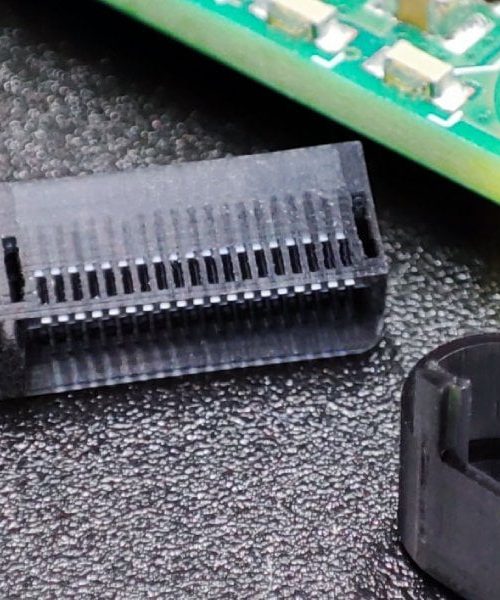

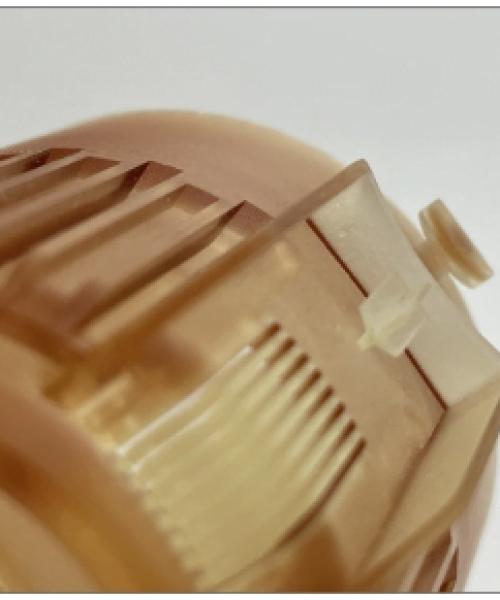

A broad resin portfolio—including biocompatible, engineering and ceramic-filled options—lets you match material performance to your application. Need leak-free channels or multi-layer assemblies? We finish prints in-house with CNC routing, laser cutting and diffusion bonding, creating production-ready components that rival traditional micro-machining in speed and cost.

If you need reliable, low-volume or prototype micro parts fast, IPFL’s end-to-end service and industry-leading micro 3D printers deliver the accuracy, surface finish and turnaround you expect. Get in touch for a rapid quote on your next micro manufacturing project.

Micro 3D printing with BMF (Boston Micro Fabrication) technology enables the production of ultra-precise parts with microscale features, fine tolerances, and true-to-CAD dimensional accuracy. Using Projection Micro Stereolithography (PµSL), BMF’s 3D printers achieve resolutions down to 2μm, making them ideal for small, intricate components that traditional manufacturing methods or standard 3D printing technologies can’t handle.

BMF micro 3D printing brings micron-level precision, repeatability, and design freedom to industries where tolerance matters and miniaturisation is critical.