UK Micro 3D Printing Service for fine featured, precision components

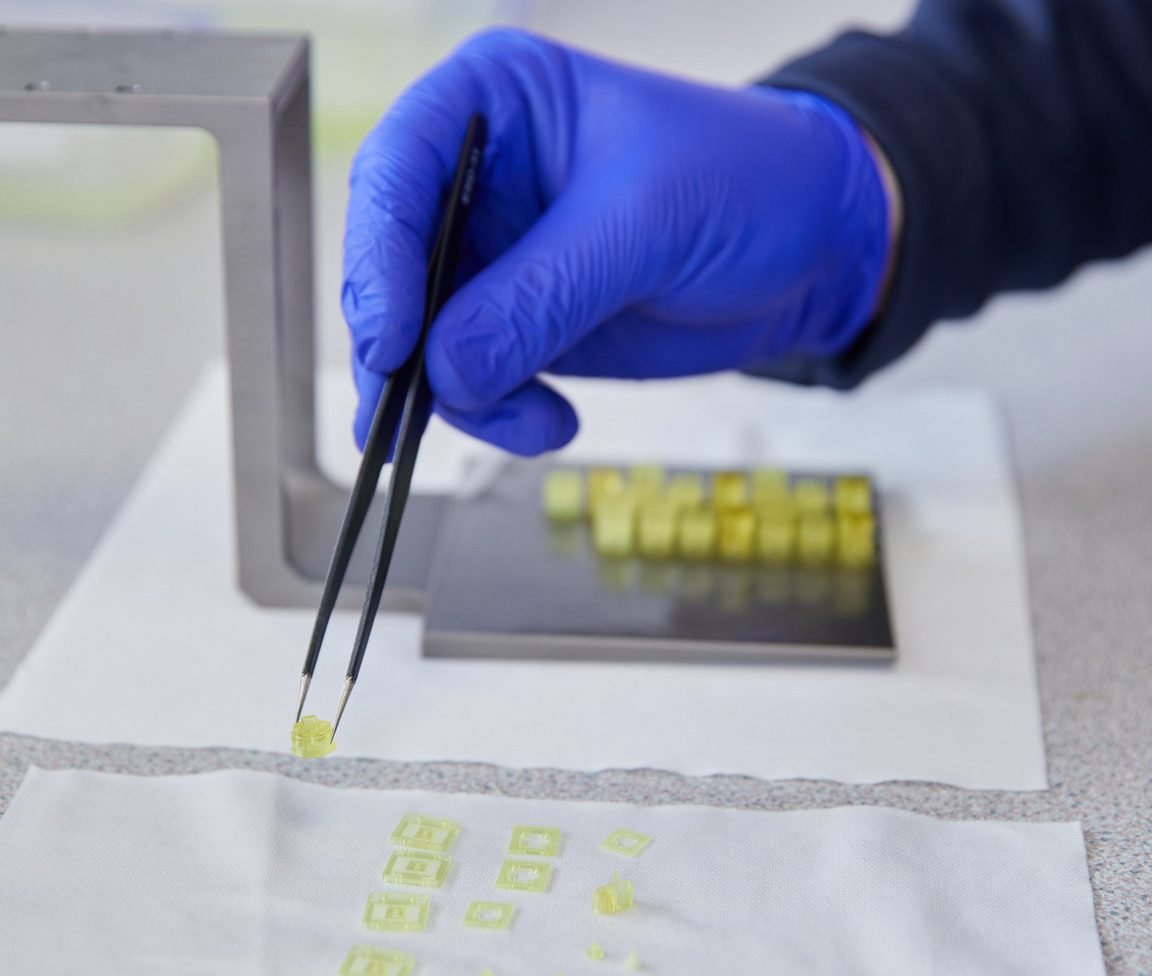

Harness our BMF S240 PµSL service to create micro parts with unrivalled 10 µm resolution and ±25 µm accuracy—ideal for microneedles, microfluidics, MEMS and other high‑precision components. At IPFL, we’re excited to offer our clients the cutting-edge capabilities of the BMF microArch® 10μm series 3D printers. This technology represents a significant leap in our micro-manufacturing capabilities, allowing us to deliver ultra-high resolution, accuracy, and precision.

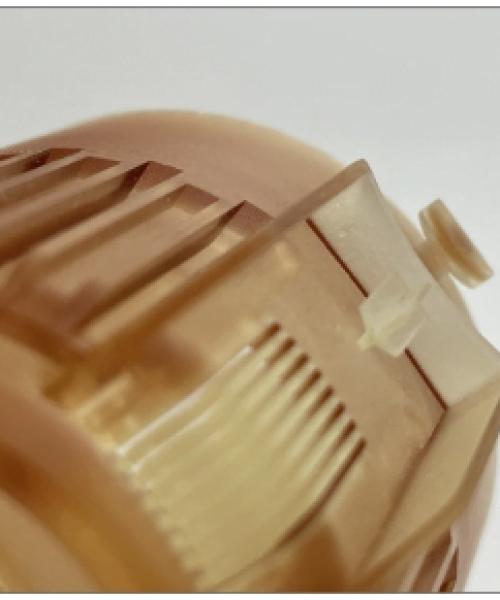

Achieve extreme feature fidelity with 10 µm XY resolution that reproduces crisp edges, sharp corners and true-to-CAD geometries—even for features as small as 25 µm. Closed-loop control, in-situ monitoring and our ISO 9001-certified QMS deliver production-grade repeatability and batch-to-batch consistency. Tool-free printing accelerates development, letting you iterate designs in days rather than weeks, while cost-effective scalability allows you to produce a single prototype or thousands of identical end-use micro components. The system maintains ±25 µm dimensional accuracy across a 100 × 100 × 75 mm build area with layer thicknesses from 5 µm to 40 µm, and it supports certified biocompatible and high-temperature resins to meet demanding application requirements.

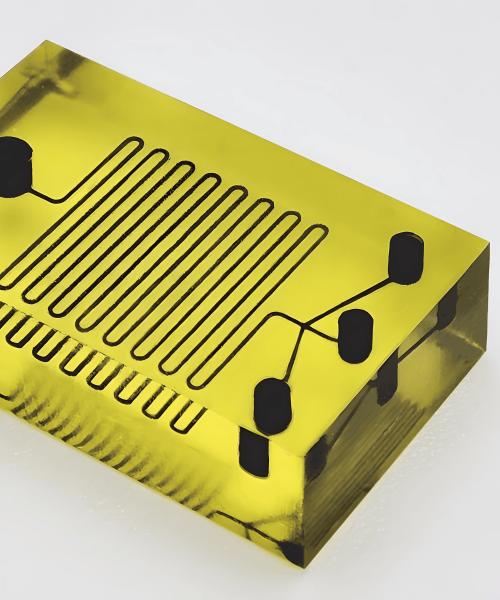

The BMF microArch® 10μm series, is Boston Micro Fabrication’s micro-precision additive-manufacturing platform that uses Projection Micro Stereolithography (PµSL) to build polymer or composite parts. It uses a UV-LED light source to cure photosensitive resin with an optical resolution of 10μm in a step-and-repeat process. This method provides exceptional detail and surface finish (0.4-0.8µm Ra on top surfaces and 1.5-2.5µm Ra on sidewalls), making it ideal for industrial prototyping and short-run production. Across a 100 × 100 × 75 mm build area, PµSL lets engineers go from micro-scale prototype to high-volume production for applications like microfluidics, MEMS and medical devices—without any custom tooling.

The 10μm series excels in producing highly precise micro parts required in various sectors, including microelectronics, medical devices, and research institutions.

Medical | Electronics | Microfluidics | Micro-mechanical | Education/research |

|

|

|

|

|

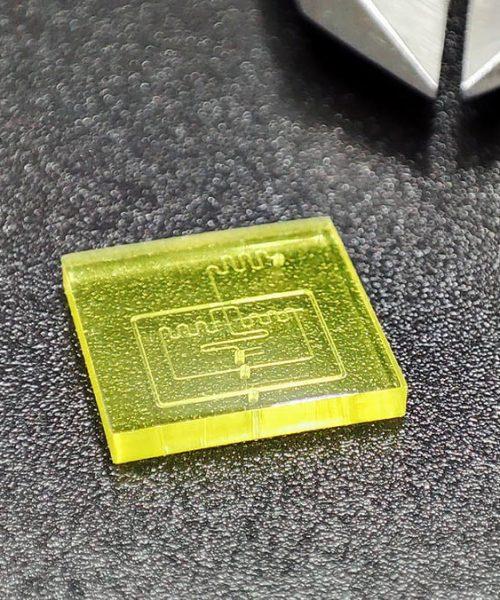

IPFL specialises in the manufacture of microfluidic devices using high-resolution additive manufacturing, including Projection Micro Stereolithography (PµSL) from BMF (Boston Micro Fabrication). This technology enables the rapid production of custom microfluidic chips, manifolds, and multi-channel systems with ultra-fine detail and tight tolerances.

We print complex microfluidic structures with features down to 10 μm, using biocompatible, chemical-resistant, and optically clear resins. These parts support fluidic systems with embedded connectors, ports, and sealing features, reducing assembly steps and improving performance.

Ideal for applications in Lab-on-a-Chip (LOC), Organ-on-a-Chip, Point-of-Care Diagnostics, Drug Delivery Systems, Environmental & Bio-Sensing Devices, Chemical Mixing, Sorting & Gradient Generation, and Microreactors for R&D and pharma.

Accelerate your fluid analysis projects with precise, production-ready microfluidic parts.

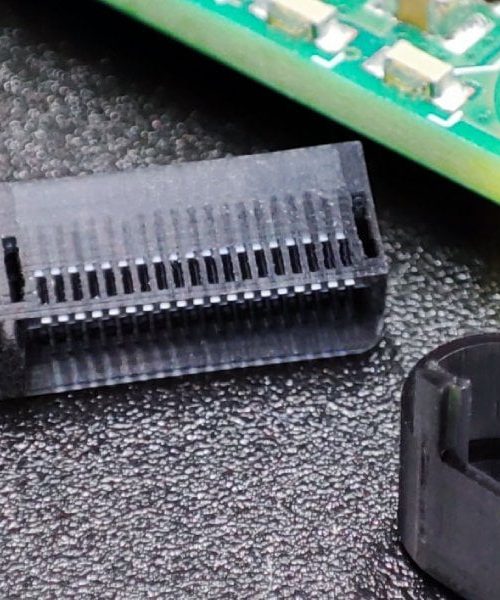

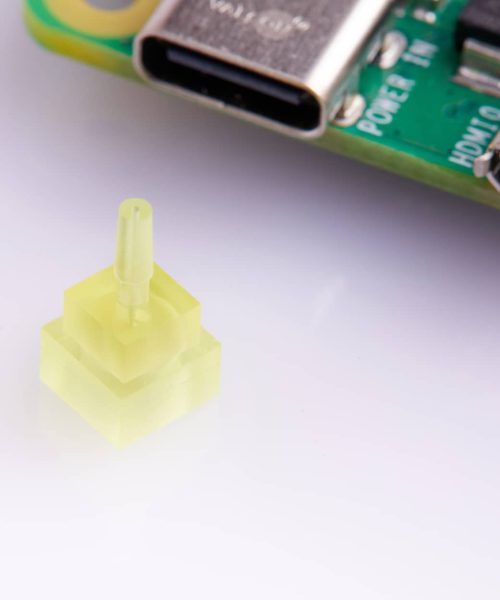

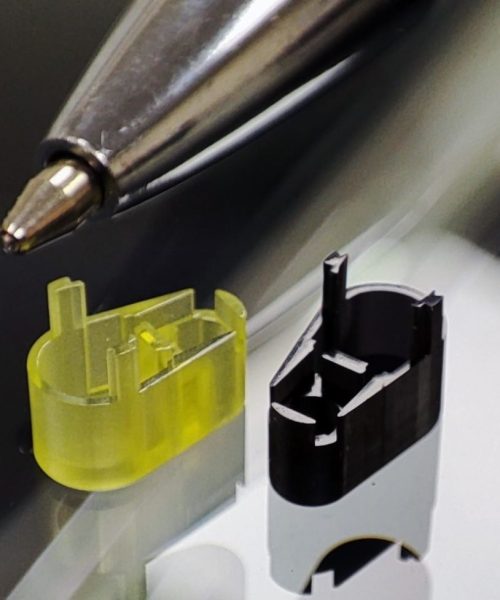

Micro 3D printing solutions for the electronics industry using high-resolution additive manufacturing, including Projection Micro Stereolithography (PµSL) from BMF (Boston Micro Fabrication). This technology enables the fabrication of highly accurate micro components essential to modern electronics.

We manufacture precision parts such as custom sockets, connectors, sensor housings, component enclosures, and microstructured insulation or spacers, all with feature sizes down to 2–10 μm. Parts are printed in engineering-grade, biocompatible, chemical-resistant resins with optional thermal and dielectric properties.

Ideal for advanced electronics development, semiconductor testing, wearables, MEMS integration, PCB component interfaces, and miniaturised optical or sensing systems. We can incorporate snap fits, alignment features, and fine mounting geometries into your design.

Get precise, compact, and complex parts for next-gen electronics with micro 3D printing from IPFL.

IPFL supports scientific research and academic innovation with ultra-precise micro 3D printing, powered by high-resolution additive manufacturing and Projection Micro Stereolithography (PµSL) from BMF (Boston Micro Fabrication).

We produce custom microscale components for experimental setups, including reaction chambers, test structures, and miniaturised lab tools, all with features as fine as 2 μm. Parts are printed in biocompatible, chemical-resistant, and optically clear resins, ideal for lab use.

Applications include fluid analysis, biomedical device prototyping, optomechanical systems, and microreactors for R&D. Our process enables rapid iteration, complex geometry, and seamless integration into research workflows.

Accelerate discovery with high-precision microfabrication for advanced research.