Micro 3D Printing Service UK - ultra fine feature, precision parts

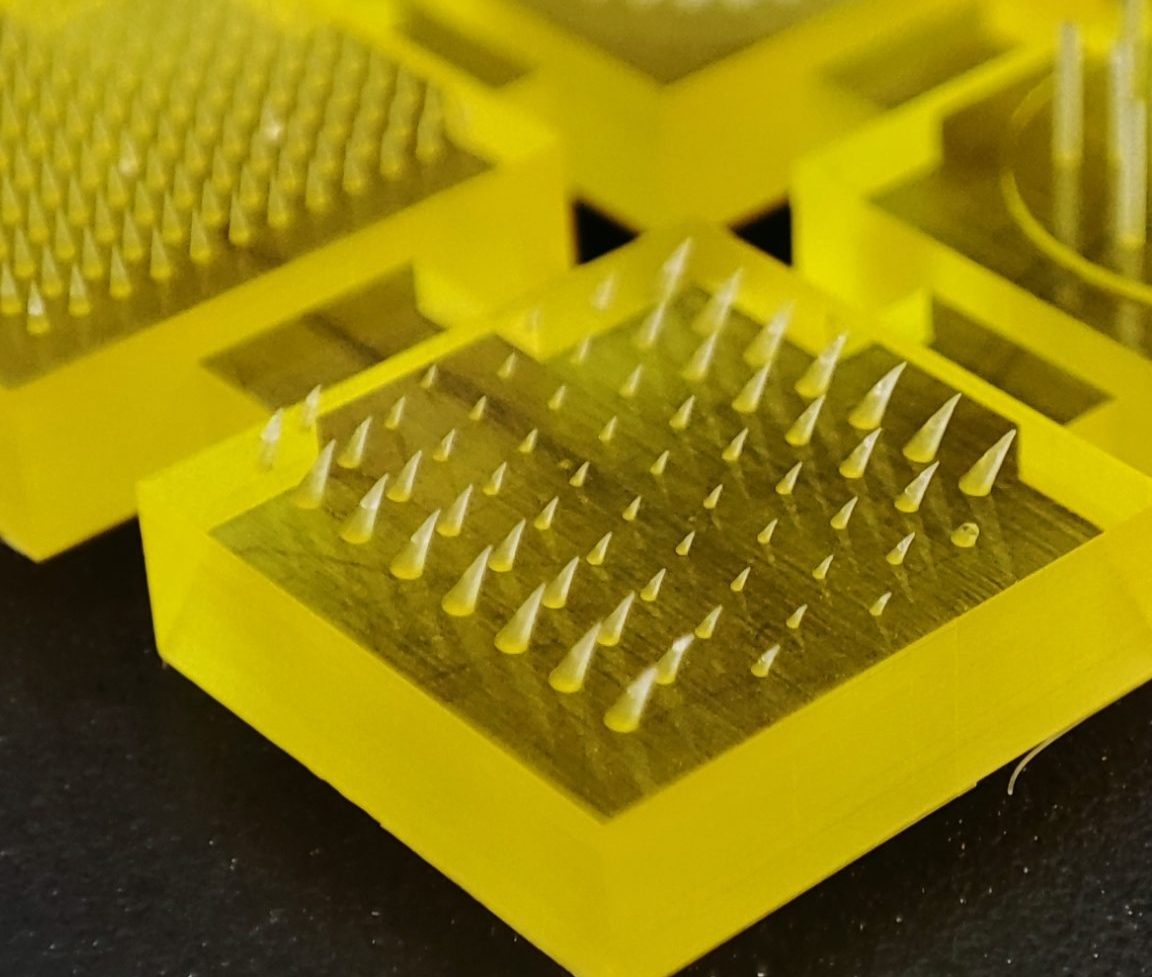

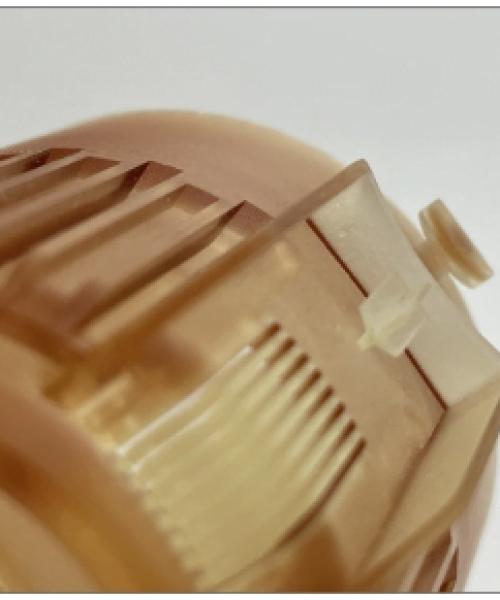

Revolutionizing Micro-Manufacturing: IPFL’s 2μm Resolution 3D Printing.IPFL proudly introduces the BMF microArch® S230 2μm PµSL, a system that sets new standards in micro-precision 3D printing. As the first and only service provider of this technology in Europe, we’re bringing unprecedented capabilities to our clients.Attain ultra-high feature fidelity with a 2 µm XY resolution that preserves razor-sharp edges, crisp corners and true-to-CAD geometries—even on details as small as 10 µm. Closed-loop optics, real-time process monitoring and our ISO 9001-certified quality-management system ensure production-grade repeatability and consistent batch-to-batch results. Because the process is tool-free, you can iterate multiple design revisions in days instead of weeks, then scale seamlessly from a single prototype to thousands of identical end-use micro-components. Within its 100 × 100 × 75 mm build envelope, the system holds tolerances to ±10 µm and offers layer heights from 2 µm to 25 µm. A growing portfolio of certified biocompatible and high-temperature resins supports demanding medical, electronics and industrial applications while meeting rigorous regulatory requirements.

Boston Micro Fabrication’s microArch® 2 μm series is a micro-precision additive-manufacturing platform built on Projection Micro Stereolithography (PµSL). Using a high-intensity UV-LED array, it cures photosensitive polymers or composites at an optical resolution of just 2 μm via a step-and-repeat exposure. The process yields sub-micron surface finishes—typically 0.2–0.5 µm Ra on horizontal faces and 0.8–1.2 µm Ra on vertical walls—making it a strong fit for both functional prototypes and low-volume production. Engineers can move seamlessly from single micro-scale parts to scaled batches across the 100 × 100 × 75 mm build envelope, eliminating the need for custom tooling in applications such as microfluidics, MEMS and next-generation medical devices.

The 2μm series precision and versatility make them ideal for any industry requiring microscale parts with complex geometries and tight tolerances. With the introduction of the 2 micron printer, IPFL continues to expand the frontier of what’s possible in additive manufacturing.

Medical | Electronics | Microfluidics | Micro-mechanical | Education/research |

|

|

|

|

|

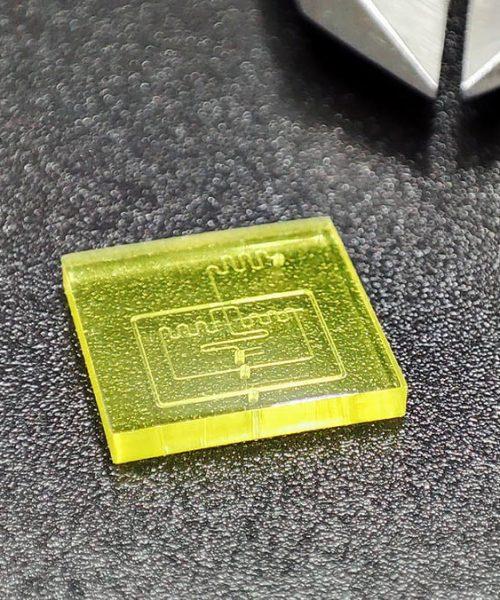

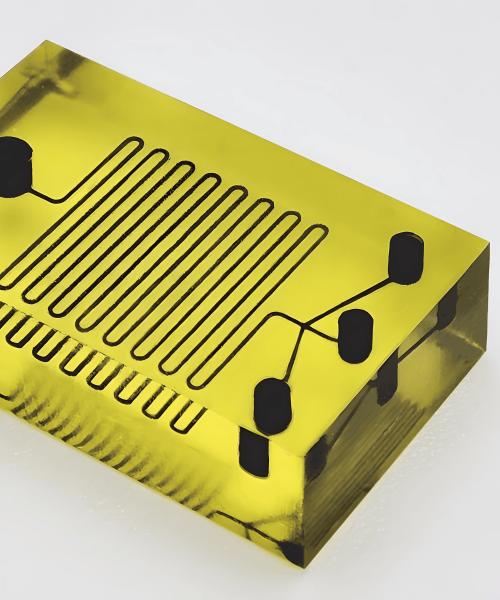

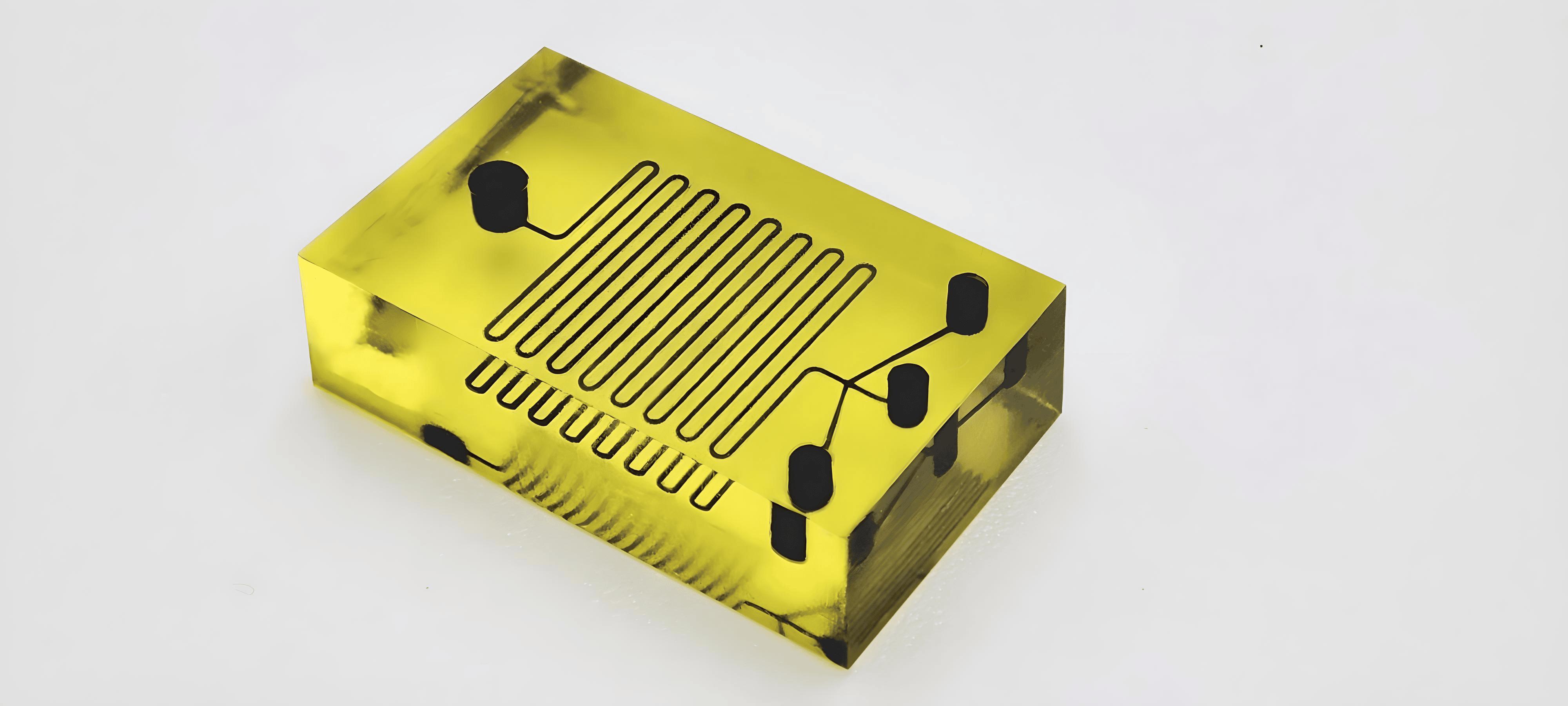

IPFL delivers high-precision 3D printed solutions for microfluidic systems, utilising Projection Micro Stereolithography (PµSL) from BMF (Boston Micro Fabrication) — a leader in micro-scale additive manufacturing.

We produce custom fluidic components, including multi-channel chips, flow manifolds, and complex internal geometries, with feature sizes as small as 10 μm. Our resins are optically clear, biocompatible, and chemically robust, making them ideal for functional lab use.

Applications include Organ-on-a-Chip, Lab-on-a-Chip, point-of-care diagnostic tools, drug delivery platforms, biosensors, chemical mixing systems, and microreactors for pharmaceutical research.

Enable fast, flexible, and compact design of microfluidic devices with IPFL’s micro 3D printing services.

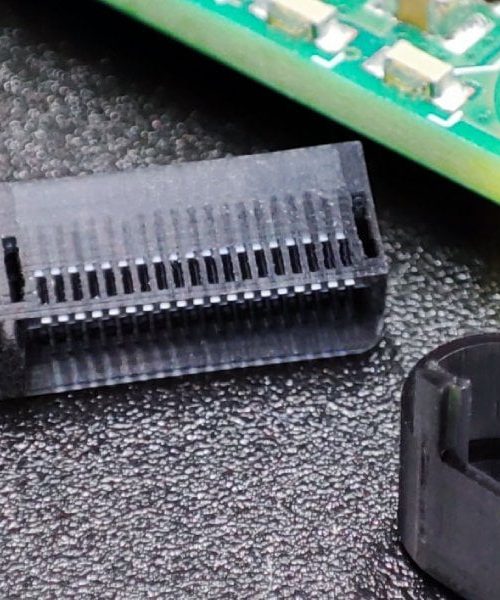

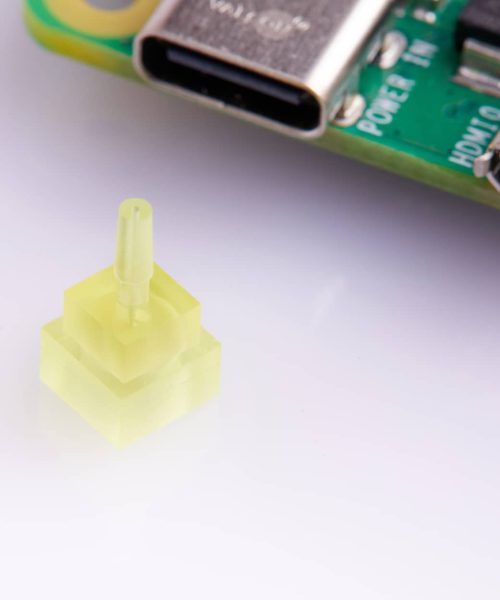

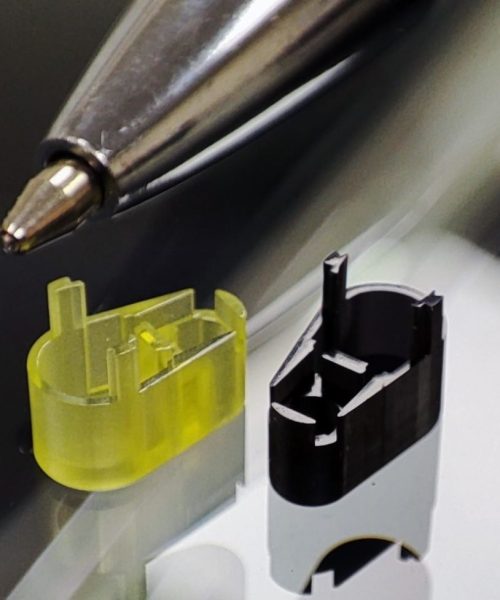

IPFL offers high-accuracy micro 3D printing services tailored for the electronics sector, powered by Projection Micro Stereolithography (PµSL) from BMF (Boston Micro Fabrication) — a leader in high-resolution additive manufacturing.

We produce detailed parts such as connectors, test sockets, sensor housings, and compact enclosures, achieving fine features between 2–10 μm. Our printed materials are chemical-resistant, biocompatible, and available with optional thermal and dielectric properties.

Perfect for wearables, semiconductor test rigs, MEMS packaging, PCB interface parts, and miniature optical systems, our service supports intricate designs including snap fits, mounting details, and tight tolerances.

Bring your electronics innovations to life with micro-precision 3D printing from IPFL.

At IPFL, we collaborate with research institutions and laboratories to deliver microscale 3D printed components using advanced Projection Micro Stereolithography (PµSL) by BMF (Boston Micro Fabrication). This cutting-edge high-resolution additive manufacturing process enables breakthrough developments in science and technology.

Our capability to fabricate miniature structures, such as custom test chambers, prototyping tools, and analytical devices, with resolution down to 2 μm, makes us a trusted partner in complex R&D.

We use optically clear, chemical-resistant, and biocompatible resins, making our parts ideal for lab-based applications including fluid analysis, biomedical testing, precision optics, and experimental microreactors.

Push boundaries in science with IPFL’s reliable microfabrication for next-generation research tools.