High-precision biocompatible resin for medical 3D printing and medtech applications

Durable and Versatile for Demanding Applications

Surgical Planning & Patient-Specific Devices

Surgeons use BMF MED anatomical models to plan complex procedures, with the material’s translucency revealing internal structures. Patient-specific surgical guides, cutting jigs, and drill templates printed in BMF MED improve accuracy during orthopaedic and maxillofacial operations. The material’s sterilizability means these guides enter the operating theatre alongside metal instruments.

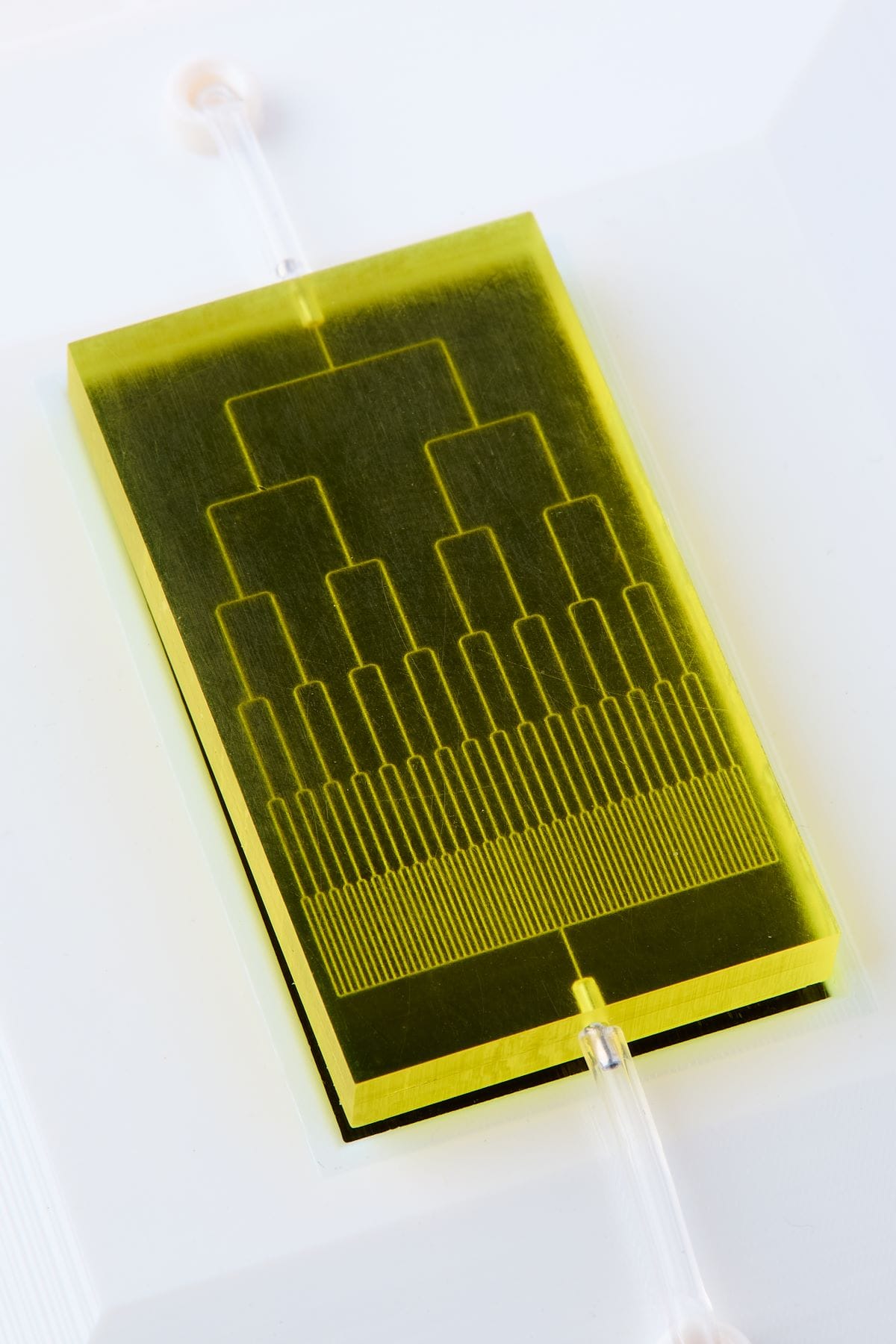

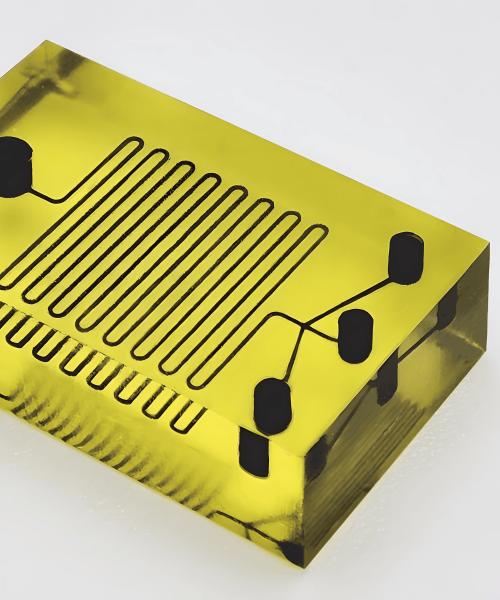

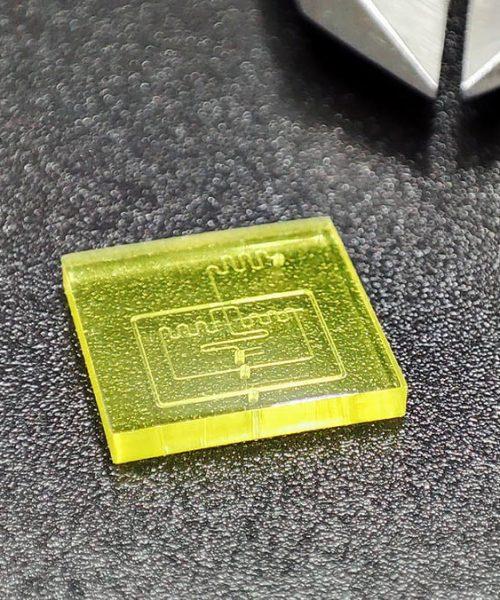

Microfluidics & Diagnostic Devices

Lab-on-chip developers exploit BMF MED’s precision to create integrated microfluidic channels, reaction chambers, and mixing networks under 100 microns. The translucent amber allows optical detection systems to monitor fluid behaviour and chemical reactions. Diagnostic cartridge housings benefit from BMF MED’s chemical resistance against reagents and sample fluids.

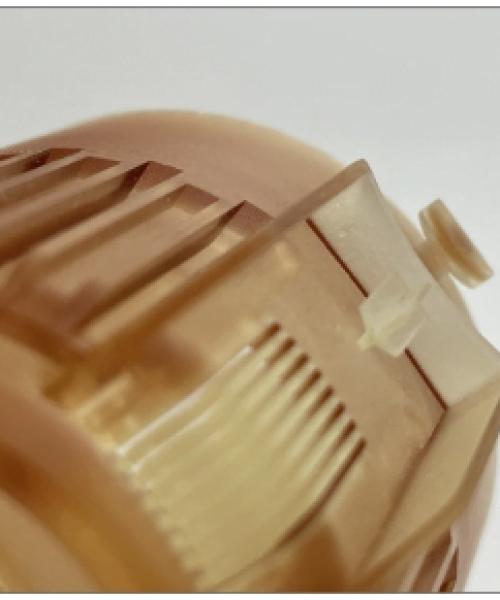

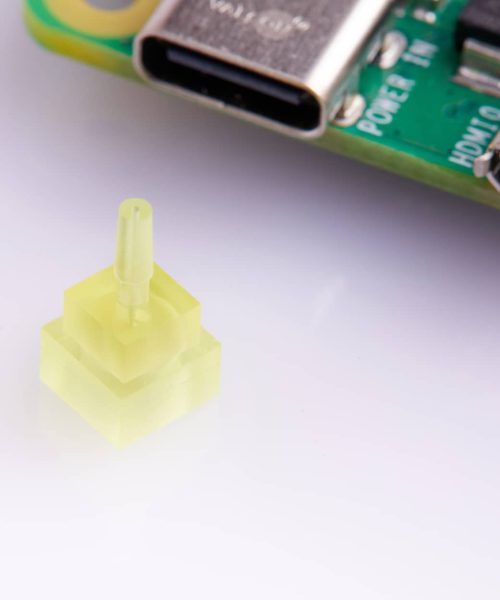

Drug Delivery Components

Pharmaceutical researchers prototype metered-dose inhaler components, autoinjector housings, and controlled-release implants using BMF MED. The material’s biocompatibility permits in vitro and animal testing of drug-contacting surfaces. Micro-scale features enable precise flow orifices and dosing mechanisms that are difficult to achieve through traditional manufacturing.

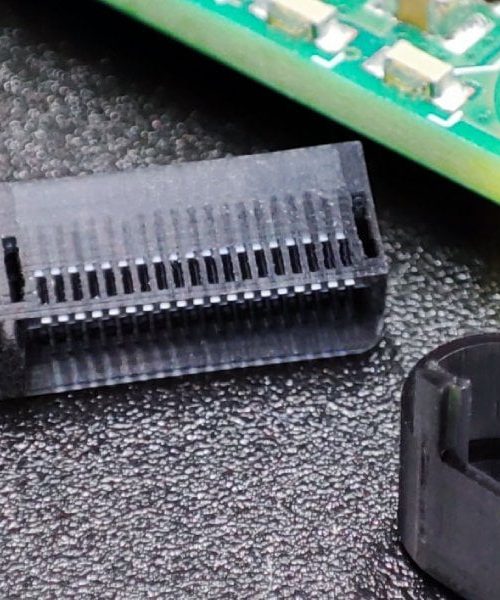

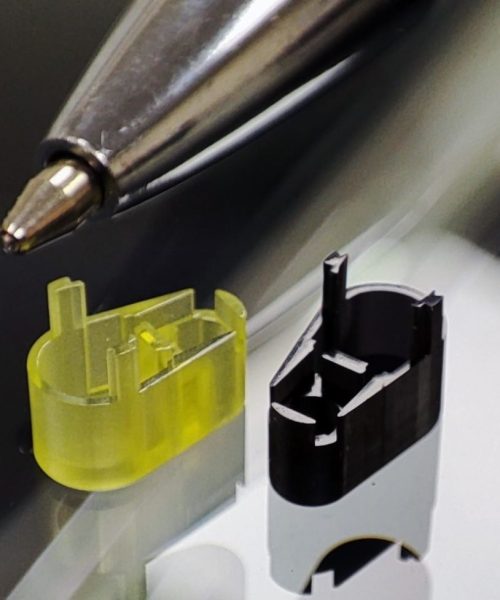

Medical Device Enclosures

Electronics housings for wearable monitors, implantable sensors, and handheld diagnostic tools benefit from BMF MED’s combination of rigidity and impact resistance. The material shields sensitive components while maintaining a professional finish suitable for clinical environments. Integrated snap features and internal bosses eliminate secondary assembly operations.