Polyjet Multi-material (rigid/flexible) 3D Printing Services

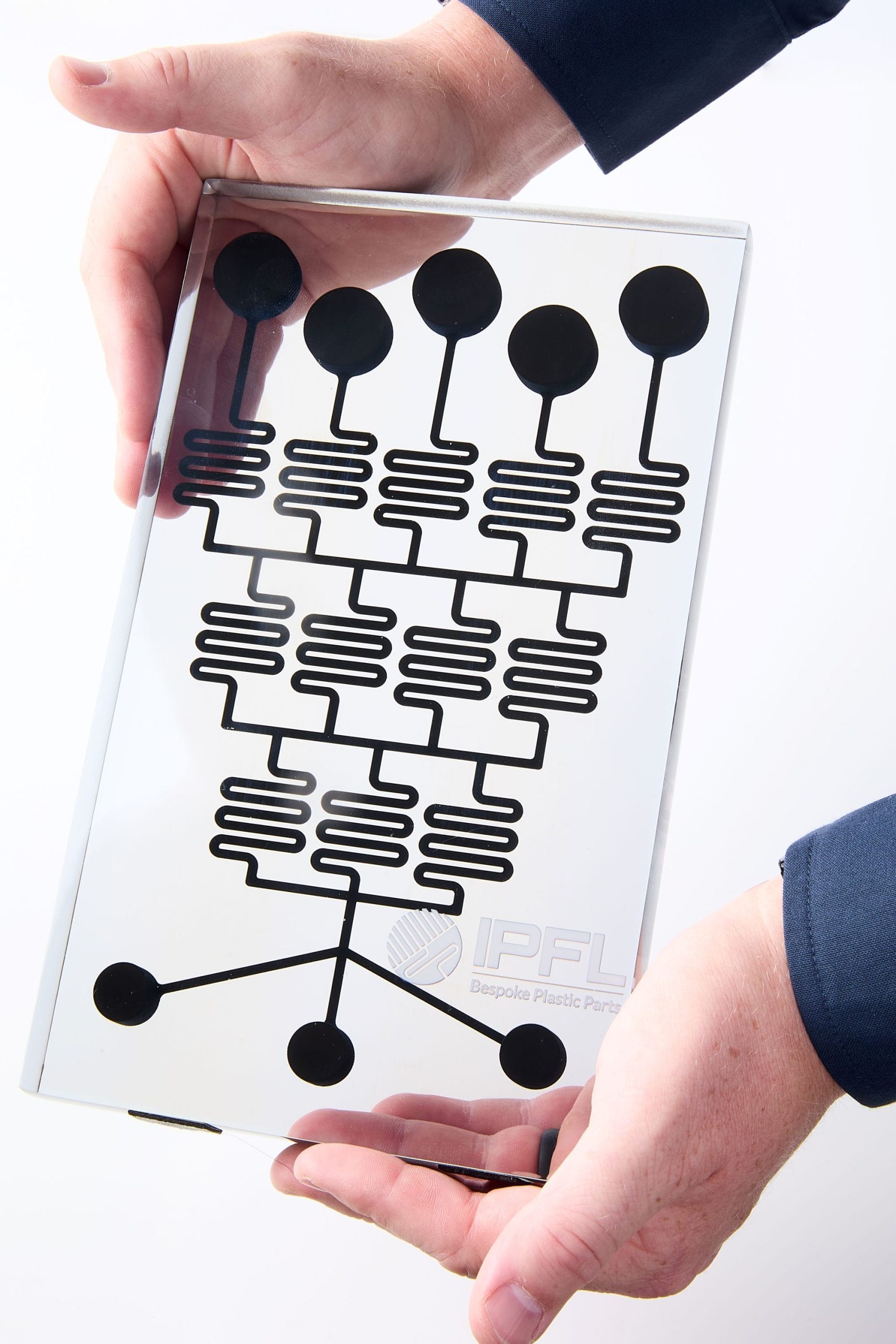

IPFL’s PolyJet 3D Printing Service is a high-resolution additive manufacturing process that uses inkjet-style print heads to deposit layers of liquid photopolymer resin onto a build platform. Each layer is instantly cured with UV light, building parts with exceptional detail, smooth surfaces, and multi-material capabilities.

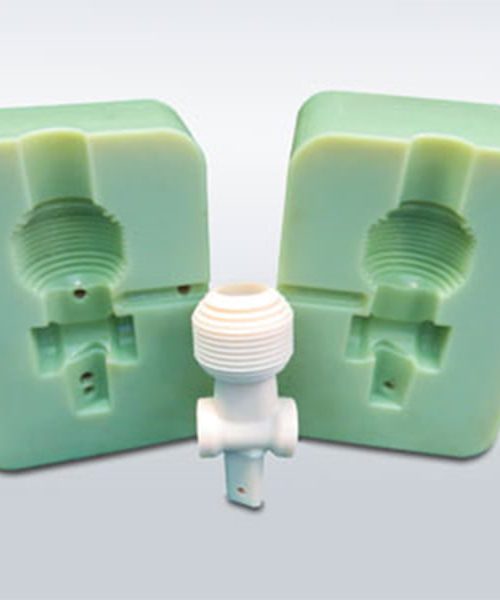

PolyJet 3D printing, developed by Stratasys, can produce parts with varying material properties — from rigid to flexible, transparent to opaque — all in a single build. It’s ideal for visual models, form and fit testing, medical device prototypes, and complex assemblies.

This technology excels at fine features, thin walls, and smooth finishes that require minimal post-processing. It is widely used for presentation-ready parts, biocompatible components, and multi-material prototypes where realism and accuracy are essential.

PolyJet printing offers Full-colour or multi-material options, Rubber-like and clear material combinations, Accurate and intricate geometry reproduction, Biocompatible and medical-grade resin options

PolyJet is perfect for precision 3D printing needs — detailed, versatile, and presentation-ready right off the printer.

PolyJet 3D printing is a high-resolution additive manufacturing technology that works by jetting tiny droplets of liquid photopolymer resin onto a build platform, layer by layer. Each droplet is instantly cured by UV light, solidifying the material and building the part with extreme precision.

Multiple materials can be jetted simultaneously, allowing for multi-material and multi-colour printing within a single build. A gel-like support material is printed alongside the part to support overhangs and complex geometry — this is easily removed after printing, leaving a clean, detailed finish.

Key features of the PolyJet process include:

With its exceptional detail, material versatility, and presentation-ready finish, the PolyJet process is ideal for realistic prototypes, functional testing, and complex design verification across medical, product design, and electronics industries.

PolyJet 3D printing offers unmatched flexibility, precision, and surface quality for applications where appearance, accuracy, and complexity are key. With the ability to combine materials, colours, and textures in a single print, PolyJet is the most versatile 3D printing technology available for creating highly realistic prototypes and complex assemblies.

It’s ideal for engineering teams, medical device developers, product designers, and marketing teams who need presentation-ready parts or functional prototypes that mimic production intent.

Our PolyJet 3D printing service produces components that are:

Whether you need functional prototypes, presentation models, or complex design validation, PolyJet delivers precision parts that look and feel like the final product.

Send us your CAD files or design brief, and we’ll help you choose the right PolyJet materials and finishes to bring your vision to life.