Injection moulded parts brought to market faster with lower project costs and more complex geometries by HP Multi-Jet Fusion.

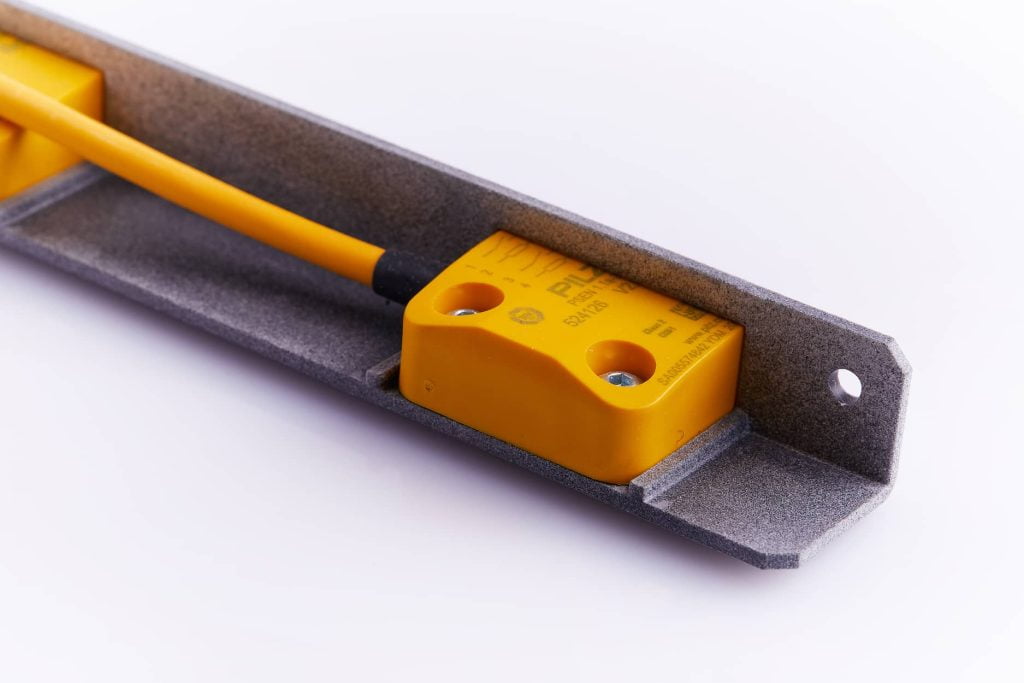

Injection moulding is a tried-and-true method of mass-producing plastic parts using the process of injected molten materials. Now 3D printing brings opportunity to cut down production time and create new avenues with complex geometric solutions. Multi-Jet Fusion (MJF) is here, and IPFL is ready to demonstrate its benefits over the old faithful. High accuracy, good surface finish, and excellent mechanical properties are just the start.

The troublesome cost and extensive time investment required for injection moulding is a production problem that requires a solution. These problems follow other concerns including:

Customers of IPFL have been lucky enough to experience the offer of fast, low-cost production parts without the traditional burdens. HP Multi-Jet Fusion with IPFL offers:

With high entry costs for injection moulding and mistakes difficult to correct, it’s hard not to consider additive manufacturing. IPFL have helped our clients through the design and manufacturing process using custom designs with improvements in function and aesthetics.

Designers and manufacturers have the flexibility of optimising their designs for purpose and functionality, not just manufacturing method.

“With MJF, mistakes can be realised and in a much shorter development time than injection moulding” – HP

HP illustrates the breakeven for investing in their 3D printer, against having parts injection moulded.

“In a landscape where additive manufacturing technologies are considered too costly or slow (or both) to be useful for wider adoption, this is a paradigm shift that makes 3D printing a viable alternative to injection moulding in mass manufacturing” – 3DP

Product value has been notably increased by utilising the high versatility of processes. These include Machining and Fabrication, post processing, polishing, bead blasting, tumbling, and dyeing—all done in-house at IPFL.

IPFL HP Multijet Fusion wep page