In the forefront of innovative medical technologies, 3D bioprinting has emerged as a groundbreaking tool, fundamentally transforming the approach to pharmaceutical research and development. With a legacy of over five decades in precision plastic component manufacturing, IPFL is proud to be constantly advancing our Micro 3D Printing services, aimed at revolutionizing drug testing and reducing reliance on animal models.

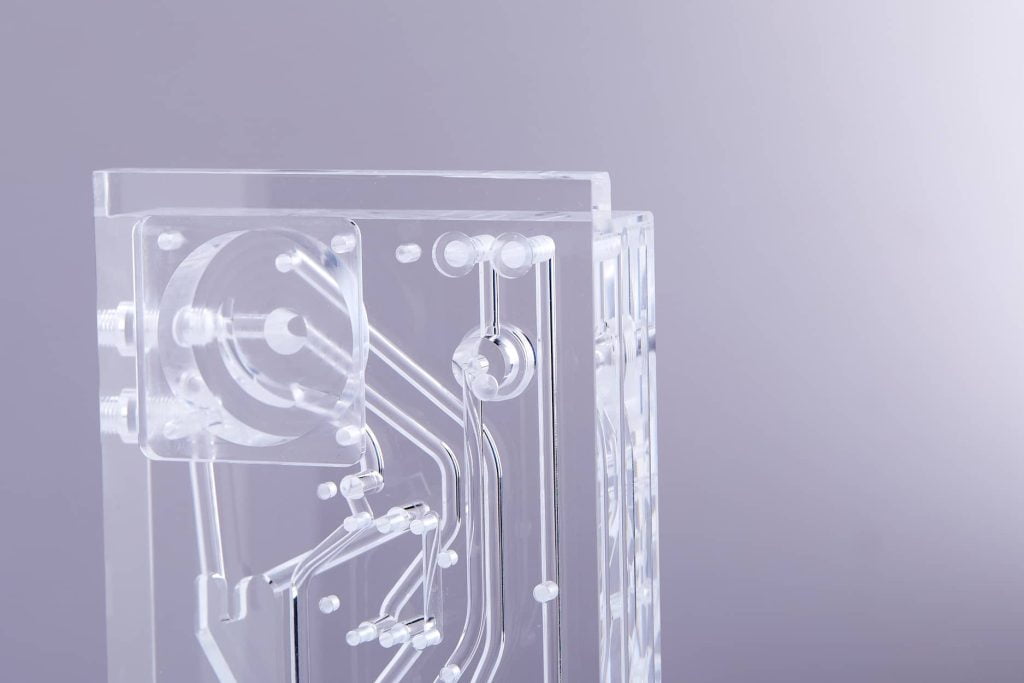

The cutting-edge technology utilised by IPFL, particularly PµSL 3D Printing, including the sophisticated PµSL (Projection Micro Stereolithography) processes offered by BMF (Boston Micro Fabrication), enables the production of intricate three-dimensional structures with exceptional resolution. These capabilities are crucial for creating complex microfluidic channels, lab-on-a-chip, organ-on-a-chip, and body-on-a-chip devices that are significantly more compact and accurate in mimicking human physiology.

A recent development by scientists from the University of Edinburgh highlights the immense potential of this technology. They have pioneered a 3D-printed body-on-chip device that could potentially replace the use of animals in early-stage drug testing. Currently, Europe utilizes approximately 80,000 animals annually in such research. IPFL’s microfluidic development supports reducing these numbers but also enhances the efficiency and accuracy of pharmaceutical testing.

These devices can illustrate how a drug circulates and interacts within human tissues and organs. Equipped with compartments that simulate major organs connected by a network mimicking the human circulatory system, it allows for a precise study of drug effects on the human body without the ethical and logistical complexities of animal testing.

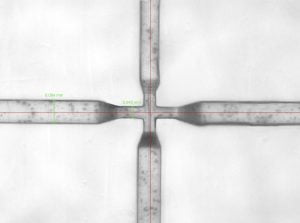

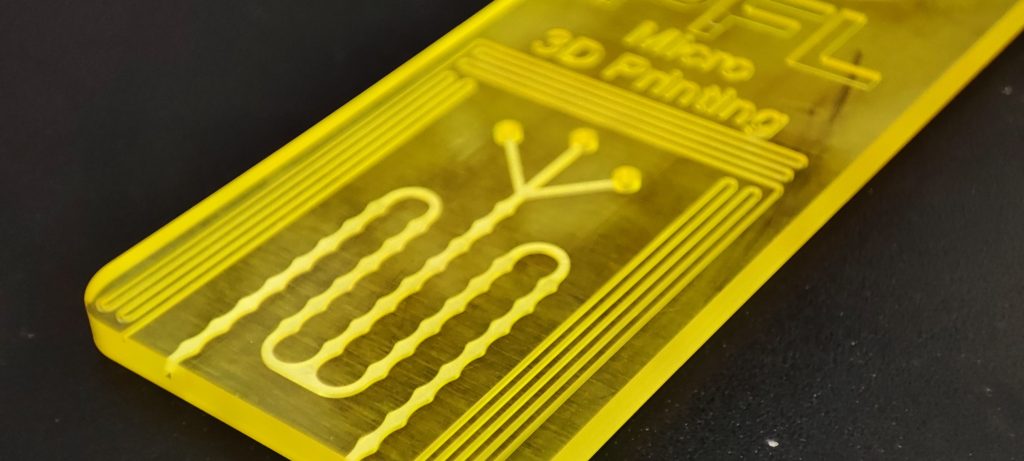

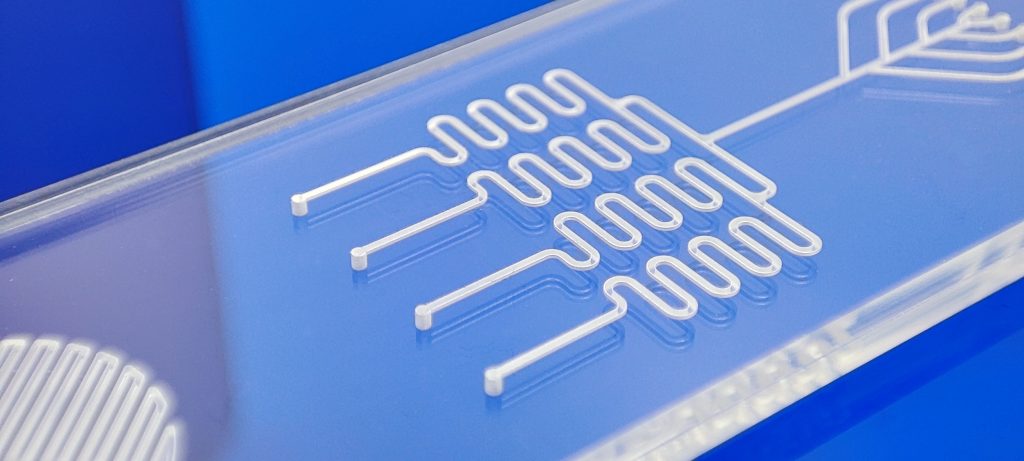

This chip boasts channels of 80 microns in diameter and intersections as tiny as 40 microns, all printed in a biocompatible material. In the pharmaceutical field, it facilitates the encapsulation of drugs into microdroplets, leading to more efficient drug delivery systems and controlled release formulations. Moreover, in medical diagnostics, it enables the creation of emulsions and microreactors for the synthesis of nanoparticles, polymers, and other materials. From enhancing drug delivery systems to advancing diagnostic tools, our micro 3D printed Double Droplet Generator chip opens new possibilities in microfluidic research.

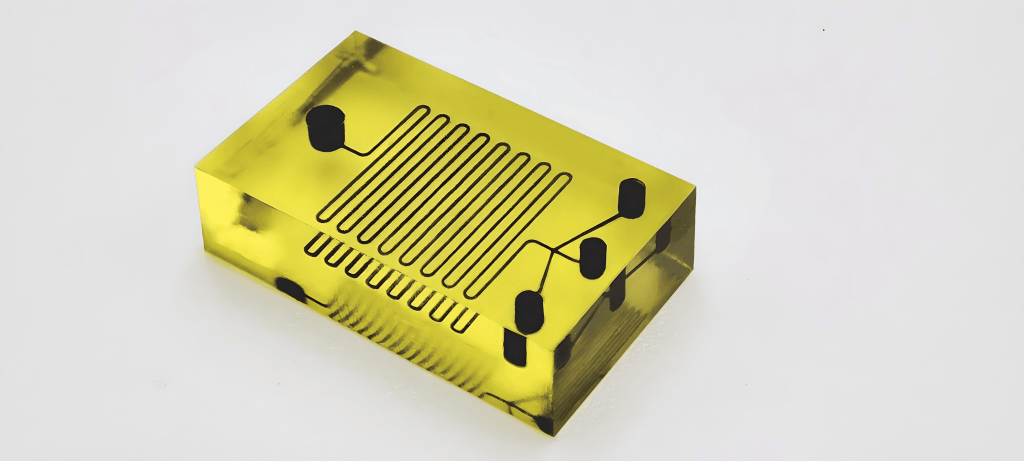

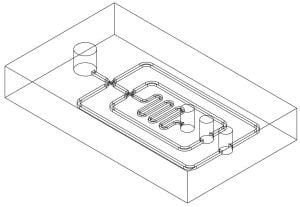

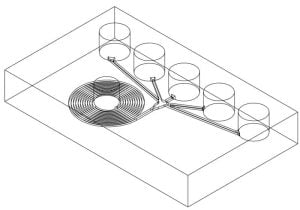

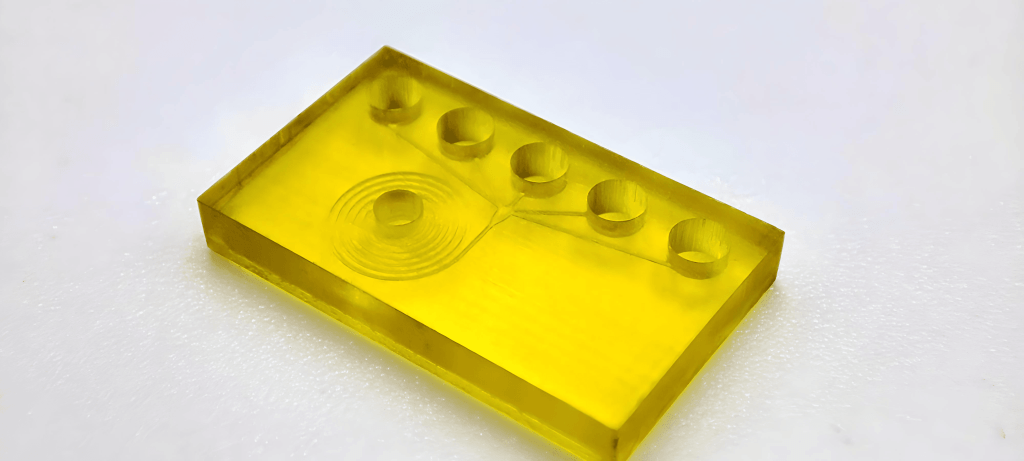

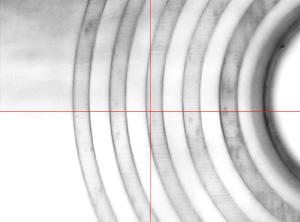

The Spiral Sorter Chip is a cell and particle sorting device. It utilizes the forces generated by rotation within the spiral channels to rapidly and precisely filter cells and particles based on their size and weight. In the medical and pharmaceutical fields, the Spiral Sorter chip finds invaluable applications. For instance, it aids in isolating specific cell populations crucial for disease diagnosis, as well as in the purification of nanoparticles by separating undesired byproducts originating from their synthesis process. This chip represents a significant advancement, offering tailored solutions for medical and pharmaceutical challenges.

Our Micro 3D Printing services are uniquely positioned to contribute to this field, offering unparalleled precision and flexibility in manufacturing components for such advanced testing devices. With resolutions down to 2µm, we can fabricate intricate channels for microfluidics and organ-like compartments that are essential for creating accurate body-on-chip devices.

As we look towards a future where drug testing is more humane, efficient, and representative of human responses, IPFL is at the forefront, ready to support researchers and pharmaceutical companies with our state-of-the-art Micro 3D Printing technologies. This not only represents a significant step forward in medical research but also underscores our commitment to innovation and excellence in the realm of microfabrication.

Join us in embracing the future of pharmaceutical research, where our advanced Micro 3D Printing capabilities pave the way for safer, more effective drug testing, minimizing the need for animal models and ushering in a new era of medical discovery.

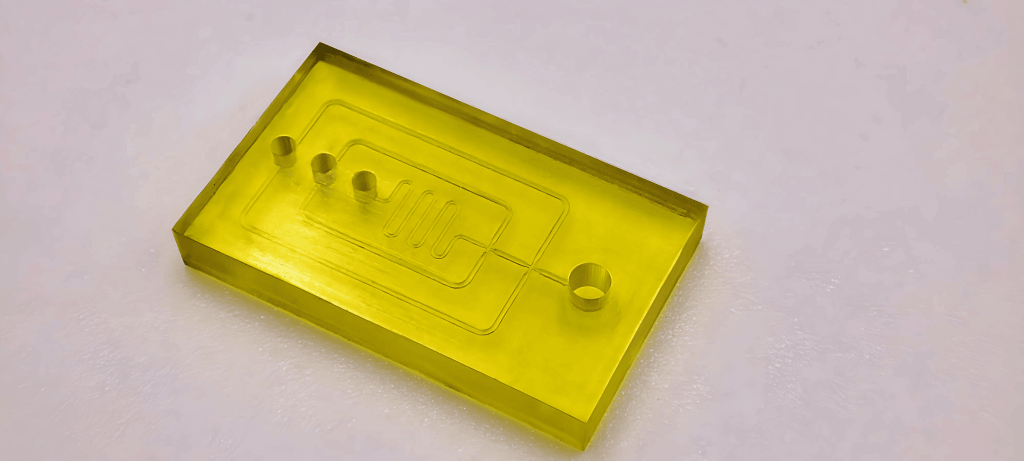

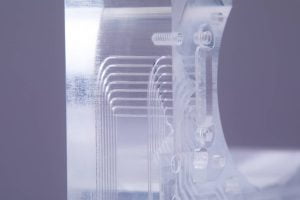

At IPFL, our expertise extends beyond micro 3D printing to include state-of-the-art diffusion bonding services, using advanced polymers such as acrylic, COC (Cyclic Olefin Copolymer), and Ultem. This process is vital for creating high-performance, multi-layered microfluidic devices that require strong, precise bonds to ensure structural integrity and optimal functionality.

Diffusion bonding at IPFL involves a carefully controlled process where acrylic, COC, and Ultem polymers are fused at a molecular level under specific temperature and pressure conditions. This technique is particularly beneficial in the fabrication of complex microfluidic systems where traditional bonding methods might compromise channel integrity or cause contamination. Our diffusion bonding capabilities enable the production of clearer, cleaner, and more durable interfaces, essential for the precise control of fluid flows in applications such as lab-on-a-chip and organ-on-a-chip technologies.

By leveraging these advanced materials, IPFL provides devices that are not only robust but also exhibit excellent chemical resistance and optical clarity, enhancing their application in sensitive biochemical environments. Our diffusion bonded microfluidic devices are designed to withstand the rigors of both experimental research and clinical diagnostics, offering enhanced reliability and performance.

This unique combination of high-precision fabrication and advanced bonding techniques positions IPFL as a leader in the field of microfluidic device manufacturing, ready to meet the evolving needs of the pharmaceutical and biomedical industries. Our commitment to innovation and quality ensures that we continue to offer our clients the very best in microfabrication solutions, driving forward the possibilities of medical research and diagnostics.

Contact the IPFL team now to discuss your project:

sales@ipfl.co.uk

01992 893231

Or start uploading your designs HERE

Industrial Plastic Fabrications Ltd.